Manufacturer of energy storage device models

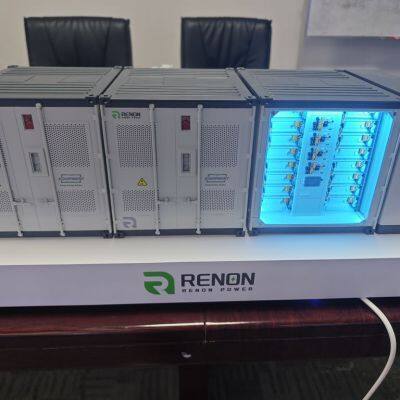

Case Study on Model Production of Energy Storage Cabinet with Lighting Display

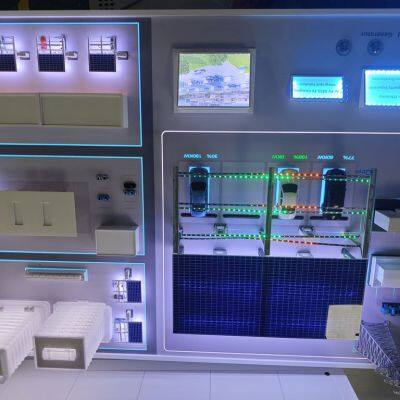

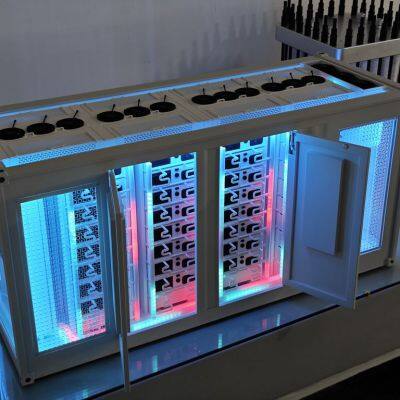

This project is a 1:5 scale energy storage cabinet system model designed for an energy solution provider, which requires the integration of dynamic lighting effects to simulate real working conditions, and ultimately safely transported to Europe for international exhibition display. The model requires a reproduction degree of over 90% in appearance, texture, and lighting interaction, and can withstand the severe test of long-distance international transportation.

1、 Material selection and structural design

Based on factors such as vibration, temperature and humidity changes that may be encountered during export transportation, material and structural design should prioritize durability and stability.

Main material: The main structure of the cabinet is made of aviation aluminum CNC machining. Aluminum is lightweight and has high strength, which can effectively reduce overall weight (lower shipping costs) and resist impacts during transportation. After surface pretreatment, it has excellent paint adhesion.

Internal structure: Internal details such as battery modules and electrical units are made of ABS engineering plastic combined with acrylic. The key load-bearing parts are designed with built-in reinforcement ribs to ensure that the model does not deform during repeated movement and transportation.

Panel and Window: The front and rear panels are made of 5mm thick acrylic sheets, laser cut and polished to a crystal like transparency, which not only simulates the texture of real cabinet glass fiber panels, but also provides clear windows for internal lighting display.

2、 Integration of production process and lighting system

The lighting effect is the core highlight of this model, and its integration must be carried out on the premise of ensuring structural integrity.

Precision machining and assembly: All metal and plastic parts are completed through CNC engraving and laser cutting to ensure a tight fit. The cabinet is double fixed with screw locks and high-strength metal adhesives, eliminating the need for simple bonding and avoiding the risk of adhesive failure caused by transportation vibrations.

Lighting system design:

Selection: All use SMD LEDs due to their low heat generation, small size, low power consumption, and long lifespan. According to different simulation objects, different colors are selected: green LED simulates battery display, blue LED simulates normal operation status, and red LED simulates fault alarm.

Wiring: The circuit design is concealed. The wire is made of extremely fine fluoroplastic wire, cleverly arranged in the slot of the structural component or pasted on the inner wall, without any visible wires from the outside.

Installation: The indicator light uses a fiber optic light guide point method, with a fiber optic implanted in a small hole of 0.5mm and an LED connected to the other end to achieve precise light spot effect of "rice grain size". The LED lighting inside the cabinet is installed in a hidden light slot on the top inner side, achieving a uniform and soft internal diffuse light effect through the light guiding properties of acrylic board, simulating the lighting inside the cabinet.

Control: Built in a miniature control board, controlled by a concealed toggle switch. Pre set lighting scene modes can be used, such as standby mode (only the green indicator light is always on), operation mode (the blue indicator light and internal lighting light flash slowly), and fault mode (the red indicator light flashes quickly).

3、 Surface coloring and treatment in the later stage

Surface treatment is not only for aesthetics, but also the key to protecting the model.

Spraying and protection: After polishing, the main cabinet is sprayed with primer → epoxy primer → automotive grade metal paint → high-performance polyurethane varnish. This multi-layer spraying process provides extremely high mechanical strength and corrosion resistance, effectively preventing erosion and slight scratching caused by high salt air during sea transportation.

Detail processing: All identification and warning stickers are made of high toughness water stickers and covered with a layer of clear varnish for protection to prevent detachment. Perform a slight "dry sweep" aging treatment on the edges and corners to enhance the industrial texture of the product.

Final testing: After completing all assemblies, conduct vibration testing and long-term power on aging testing to simulate transportation bumps and continuous display conditions, ensuring that every lighting unit and structural connection is foolproof.

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Customized manufacturer of energy storage cabinet models

September 11, 2025Case study on the production of high-precision energy storage cabinet display modelThis project is a 1:5 scale energy storage cabi Read More

Read More