Customized manufacturer of energy storage cabinet models

Case study on the production of high-precision energy storage cabinet display model

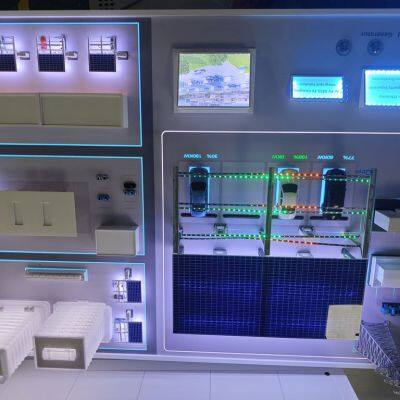

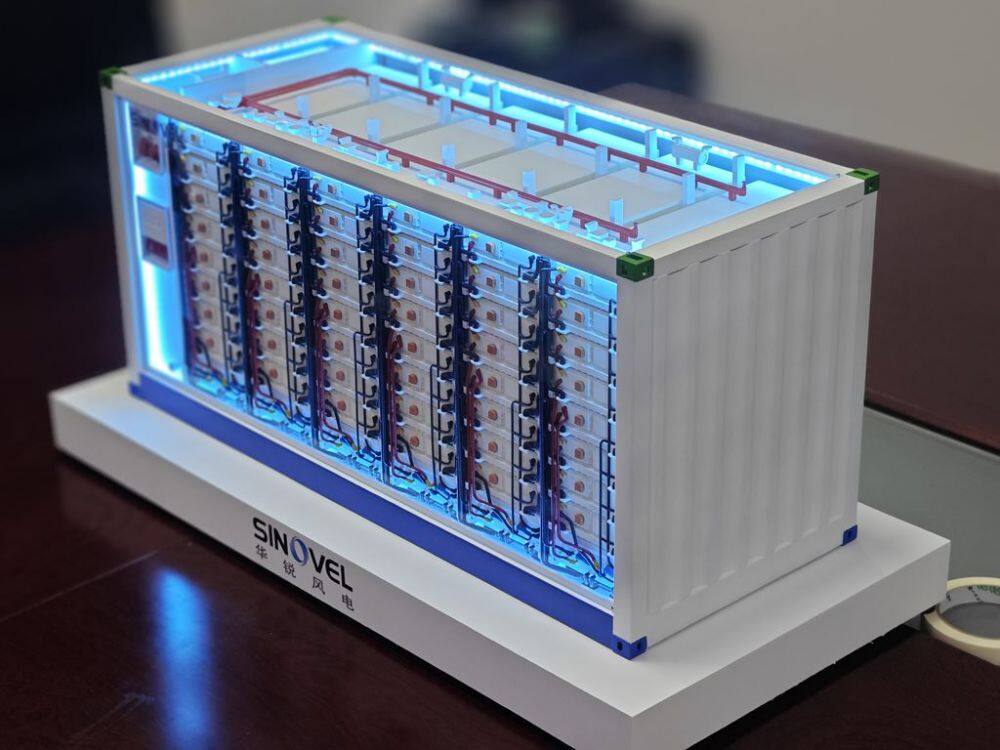

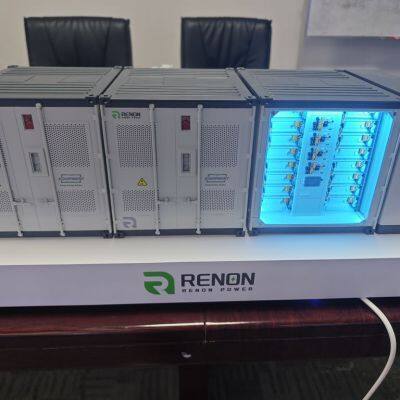

This project is a 1:5 scale energy storage cabinet system model designed for a well-known new energy technology enterprise for technology display and market promotion. The model aims to highly restore the design aesthetics, structural layout, and industrial texture of real products, with an overall restoration degree of over 90%, providing customers with an intuitive and professional visual experience.

1、 Design and Material Selection

The first step in model making is to have a deep understanding of prototype design. The team collected high-definition photos, size drawings, and close-up details of real energy storage cabinets from multiple angles to ensure that the "genes" of the model are correct.

In terms of material selection, we follow the principles of "appearance matching, easy processing, and stable structure":

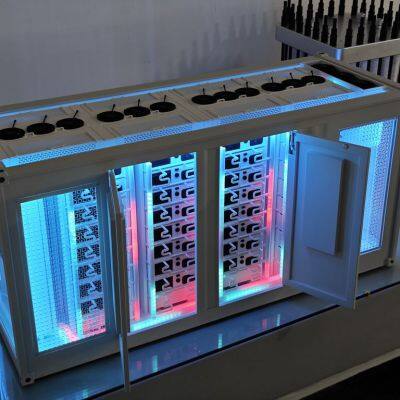

Main structure: Made of high-strength acrylic sheet and ABS engineering plastic. Acrylic is used to make cabinet side panels, top covers, and see through windows. Its high permeability and excellent surface glossiness can perfectly simulate the painted shell of a real cabinet. ABS board is used for internal brackets, battery module frames and other structural components, and its good strength and easy to bond characteristics ensure the durability of the model.

Internal components: battery module, PCS (power conversion system) unit, cooling fan and other core components, precision cut and assembled using ABS board. In order to simulate the appearance of a real battery pack, we used two colors of ABS boards, black matte and metallic silver matte, to layer and combine them, creating a sense of hierarchy between the battery cells and the module casing.

Details: Small details such as door handles, hinges, connectors, indicator lights, signs, etc. are made of CNC carved copper or aluminum parts, or use high-precision 3D printed resin parts. The use of these metal parts greatly enhances the texture and authenticity of the model.

2、 Manufacturing process and assembly

The core of model making lies in precise processing and meticulous assembly.

Precision cutting: All acrylic and ABS panels are cut using high-precision laser cutting machines. Laser cutting ensures the smoothness and flatness of each incision, with dimensional errors controlled within 0.1mm, laying the foundation for seamless assembly in the future.

Welding and bonding: Professional chloroform solvent is used for seamless bonding between acrylic sheets. After they are completely cured, the joints are almost invisible, like a whole injection molded cabinet. ABS structural components are fixed using model specific adhesive and micro screws to ensure strength and facilitate the installation and debugging of internal components.

Internal layout and wiring: completely imitating the internal layout of real products. Each set of "battery modules" and "electrical units" is precisely installed in the predetermined position. We used an extremely fine black nylon mesh to wrap the copper wire, simulating a real cable bundle, and tied and fixed it according to standard cable management methods, making the interior look orderly and full of technical sense.

Movable structure: The front and rear doors of the model have both achieved openable functions. We have installed custom proportioned miniature metal hinges and magnetic snap fasteners for it, which have a smooth opening and closing feel, and even gaps when closed, no different from a real cabinet.

3、 Surface coloring and treatment in the later stage

This is the most crucial step in improving the model's fidelity.

Surface pretreatment: Polish and polish all parts, especially the acrylic perspective window, which needs to be treated with multiple grinding pastes until it reaches a crystal like transparent effect. Clean and dust all non transparent parts in preparation for painting.

Color separation spraying:

Cabinet shell: sprayed with automotive grade metal paint. First, spray the primer to increase adhesion, then spray the main color paint (light gray specified by the customer), and finally cover it with a layer of clear varnish to protect the paint surface and bring a deep texture luster.

Internal structure: High end model paints such as Mr. Hobby and Tamiya are used for hand spray painting. The battery module shell is sprayed with matte dark gray, the top of the battery cell is sprayed with light blue to simulate an insulation cover plate, and the electrical unit is sprayed with matte black with a small amount of silver dry sweep, highlighting the details of the metal frame and heat dissipation teeth.

Aging and identification treatment: Using the "dry sweep" technique, lightly sweep the edges and corners with light colored paint to simulate real wear and tear and usage marks, increasing the thickness of the model. Finally, use high-definition water stickers to perfectly replicate all logos, warning signs, indicator light symbols, and text instructions on the product, and spray protective paint to blend them into the surface.

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More