Manufacturer of power equipment models

Case study of high-precision display model production for power equipment

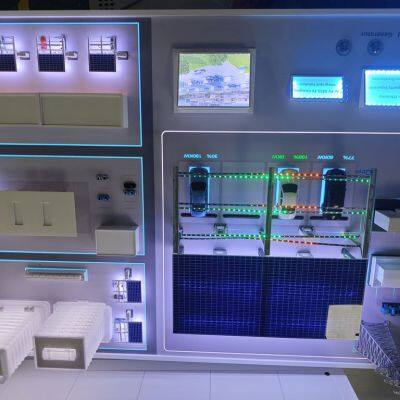

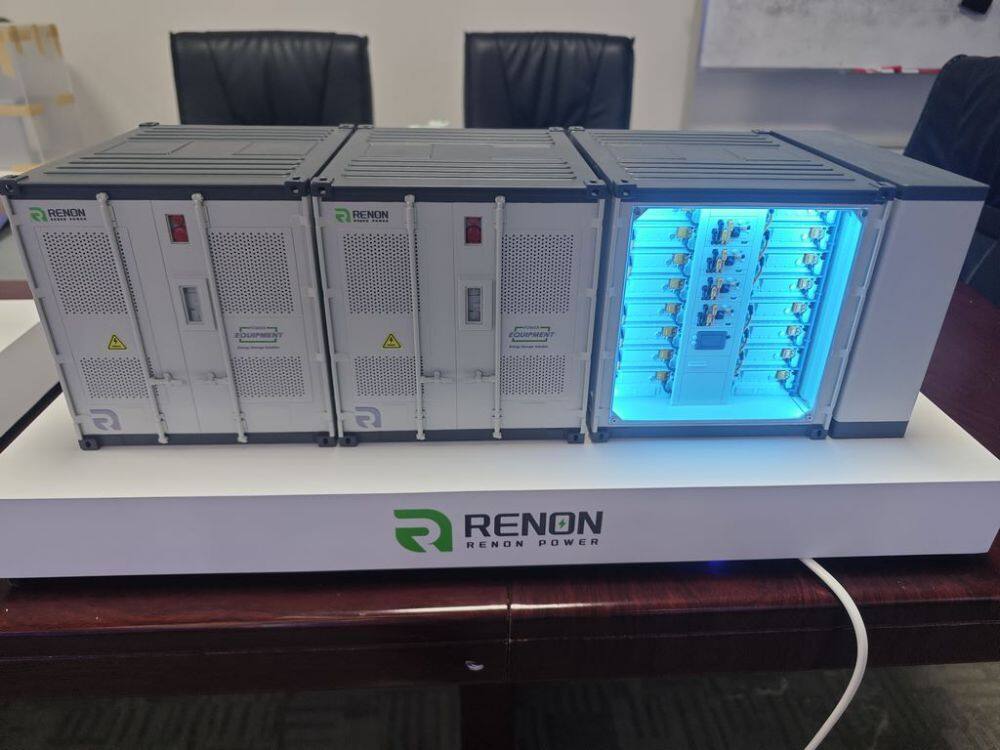

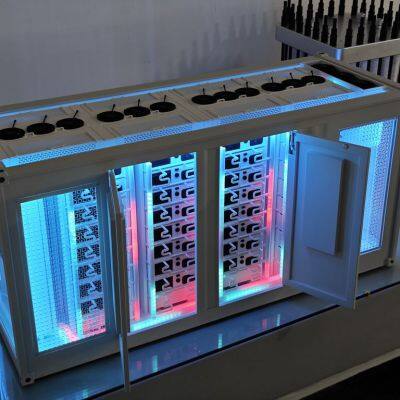

The aim of this project is to create a 1:4 scale substation equipment display model for customers, with the core goal of accurately reproducing the appearance, texture, and industrial aesthetics of real equipment. Through a precise lighting system to simulate the operating state, the restoration degree reaches over 90%, making it suitable for technology display, training and teaching, and exhibition hall display.

1、 Material selection and structural design

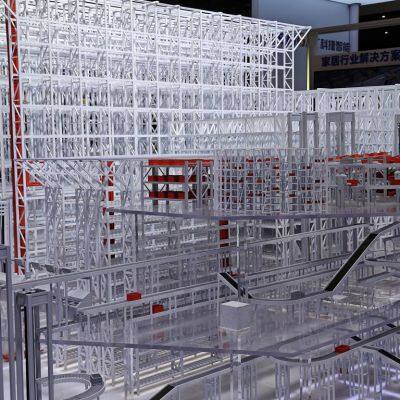

The authenticity of the model begins with precise control of the materials. The main framework adopts lightweight aluminum alloy profiles to build the internal skeleton, ensuring that the model remains absolutely stable when standing. The shell is made of high-strength ABS engineering plastic board and acrylic board composite production - ABS board shapes the unique rounded corners and ventilation grids of the equipment through hot bending process, while high transparency acrylic perfectly reproduces transparent components such as insulators and observation windows.

The internal structure adopts modular design, using ABS boards of different thicknesses stacked in layers, laser cutting the contours of key components such as coils and circuit breakers, and then manually assembling them to form a three-dimensional structure. All connecting bolts, operating mechanisms, and other details are made of brass CNC precision machining to ensure the strength and authenticity of small components. The conductive components such as grounding bars and connection terminals are etched with stainless steel to express their metallic texture.

2、 Integration of production process and lighting system

The model adopts a multi process composite manufacturing method. All sheet metal parts are laser cut to ensure contour accuracy, and key connecting parts are double fixed with mortise and tenon structure and special adhesive. Surface texture treatment is particularly important: using a carving machine to process the unique frosted texture of the equipment on the ABS board, and then using chemical solvent polishing to eliminate processing marks.

The lighting system is the technical core of this production. The status indication system adopts 0402 specification micro patch LED, which conducts the light source to a 0.8mm diameter indication hole through fiber optic light guiding technology, achieving pointer like accurate light point display. To simulate the lighting effect during device operation, three levels of lighting were set up inside the model: the warm white LED module at the top simulates ambient lighting, the blue LED strip in the middle represents electromagnetic field effects, and the red LED dot matrix at the bottom indicates the heating area.

All circuits adopt concealed wiring design, with 0.1mm diameter enameled wires embedded in pre carved cable trays, and the surface filled with special putty and polished flat. The control system adopts microcontroller programming, which can achieve smooth switching between three lighting scenarios: normal operation, overload warning, and fault alarm.

3、 Surface coloring and treatment in the later stage

The surface treatment adopts industrial grade spraying technology. Firstly, perform ultrasonic cleaning on the entire model, and then spray epoxy primer to enhance adhesion. The main color paint adopts two-component polyurethane automotive paint, which is accurately blended with equipment gray green tones and enhanced with shadow spraying techniques to enhance the three-dimensional effect.

The detail processing is particularly meticulous: using a macro spray pen to spray semi transparent blue and white on the insulator part, reproducing the translucent characteristics of the ceramic material; The grounding bar is treated with genuine electroplating technology, first sprayed with mirror silver primer and then covered with transparent yellow paint, perfectly simulating the metallic texture of copper material. All warning signs and nameplates are made using water transfer printing technology, with a pattern accuracy of 0.1mm, and finally sprayed with polyurethane matte varnish to achieve uniform glossiness.

The aging treatment uses artist grade acrylic paint for stain washing, leaving a faint dust effect in the gaps of the equipment, highlighting the layering of the structure. Finally, the edges were dry scanned with graphite powder to simulate slight wear marks on metal components, giving the model a realistic industrial feel unique to the equipment.

Recently Posted

-

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More -

Customized manufacturer of energy storage cabinet models

September 11, 2025Case study on the production of high-precision energy storage cabinet display modelThis project is a 1:5 scale energy storage cabi Read More

Read More