Customized manufacturer of energy storage equipment models

Case study on high-precision display model production of energy storage cabinet

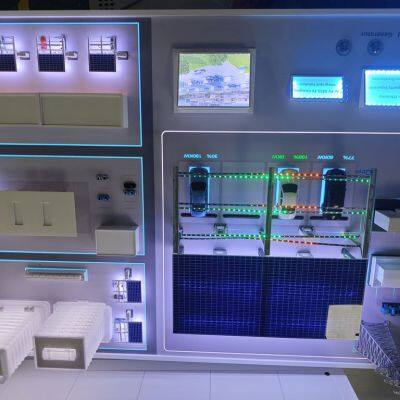

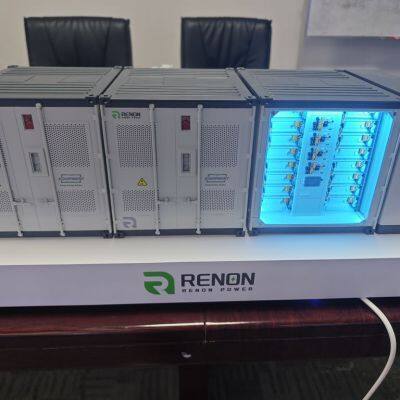

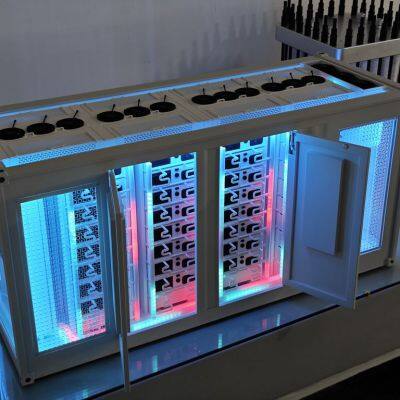

The aim of this project is to create a 1:5 scale energy storage cabinet system display model for customers. The core goal is to highly restore the appearance texture and technological sense of real products through exquisite craftsmanship, realistic material representation, and dynamic lighting effects, with a restoration degree of over 90%, for use in corporate exhibition halls, exhibitions, and customer communication.

1、 Material selection and structural design

The realism and durability of a model begin with careful consideration of materials.

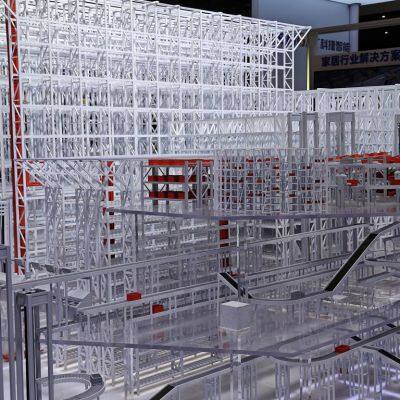

Main structure: The main frame of the cabinet is constructed with lightweight aluminum alloy profiles to ensure a sturdy and stable overall structure, fundamentally avoiding deformation. The shell is made of high-strength ABS engineering plastic board and acrylic board composite. ABS board is easy to process and can accurately shape details such as facades, ventilation openings, door panels, etc; High transparency acrylic is used to create observation windows that perfectly showcase the internal structure.

Internal modules: The core components such as battery modules and electrical units are designed with modularity. Using ABS boards of different thicknesses and colors (such as matte black and metallic silver) through laser cutting, layered stacking, and bonding to create a realistic three-dimensional sense of hierarchy and details of heat dissipation fins, accurately simulating the internal layout of real equipment.

Detail components: door handles, hinges, interfaces, indicator lampshades and other small parts, made of CNC carved brass parts or high-precision 3D printed resin parts. The ventilation grille is made of stainless steel etched sheets, with clear and uniform mesh holes, and a texture far superior to ordinary plastic parts.

2、 Integration of production process and lighting system

Lighting is the soul of a model, and its integration needs to ensure high reliability and concealment while pursuing visual effects.

Precision machining and reinforcement: All panels are processed by high-precision laser cutting machines to ensure minimal assembly gaps and strong overall integrity. The assembly process uses professional model glue combined with micro screws for double fixation, and L-shaped metal corner codes are installed inside key load-bearing parts to ensure the structural strength of the model during repeated handling and demonstration.

Lighting system implementation:

Selection and layout: All light sources use ultra micro SMD LEDs, which are small in size, low in heat generation, pure in color, and have a long lifespan. According to the different simulation functions, blue (normal operation), green (charging/sufficient battery), red (fault/warning) and other light colors are selected.

Concealed wiring: All lines are pre designed in the card slots and inner wall wiring channels of structural components, using extremely fine enameled wires or ribbon cables, and there is absolutely no visible wire from the outside, ensuring a clean and highly realistic internal visual experience.

Effect implementation:

Status indicator light: Behind the micro holes in the panel indicator area, fiber optic light guiding technology is used to accurately guide the LED light source to the surface, forming a clear, bright, and realistic light spot with a diameter of less than 1mm. Multiple dynamic effects such as constant light, slow flash, and flash can be achieved through programming on the micro control board.

Internal ambient lighting: Hidden LED soft light strips are embedded on both sides of the top of the cabinet, and the light is diffused through the milky white acrylic board to provide uniform and soft white lighting for the entire internal space, clearly showing the complex "battery module" and "wiring harness" structure, full of technology.

Control and Power Supply: Built in a miniature control board, controlled by a concealed toggle switch, capable of switching between multiple lighting scene modes. The external adopts a universal 5V DC power interface, which is safe, reliable, and easy to operate.

3、 Surface coloring and treatment in the later stage

Surface treatment is the finishing touch to achieve high fidelity and texture.

Multi layer spraying process: All components are finely polished and coated with high adhesion primer. The main color paint adopts advanced automotive metallic paint, which has been professionally adjusted to achieve zero color difference with real products. Finally, a high hardness polyurethane protective varnish is sprayed as a whole. This protective film not only gives the model a deep and advanced luster, but also makes its surface wear-resistant, scratch resistant, and fingerprint resistant.

Detail decoration and labeling: All brand logos, safety signs, and operating instructions are made using high-resolution water sticker technology and placed between the paint and varnish layers to achieve permanent protection and never fall off. Use enamel paint to lightly wash away aging stains on details such as ventilation openings and button edges, enhancing the three-dimensional feel of the model and the heaviness of real industrial products.

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More -

Customized manufacturer of energy storage cabinet models

September 11, 2025Case study on the production of high-precision energy storage cabinet display modelThis project is a 1:5 scale energy storage cabi Read More

Read More