Battery production line sand table model manufacturing factory

Lithium battery intelligent manufacturing sand table model full process solution

1、 Model presentation architecture design

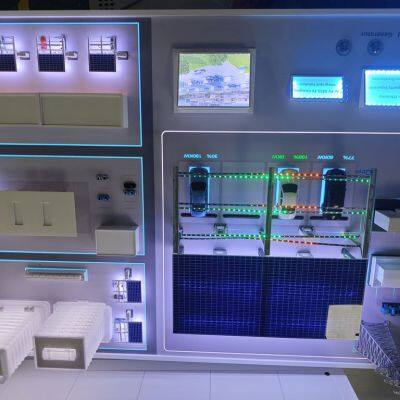

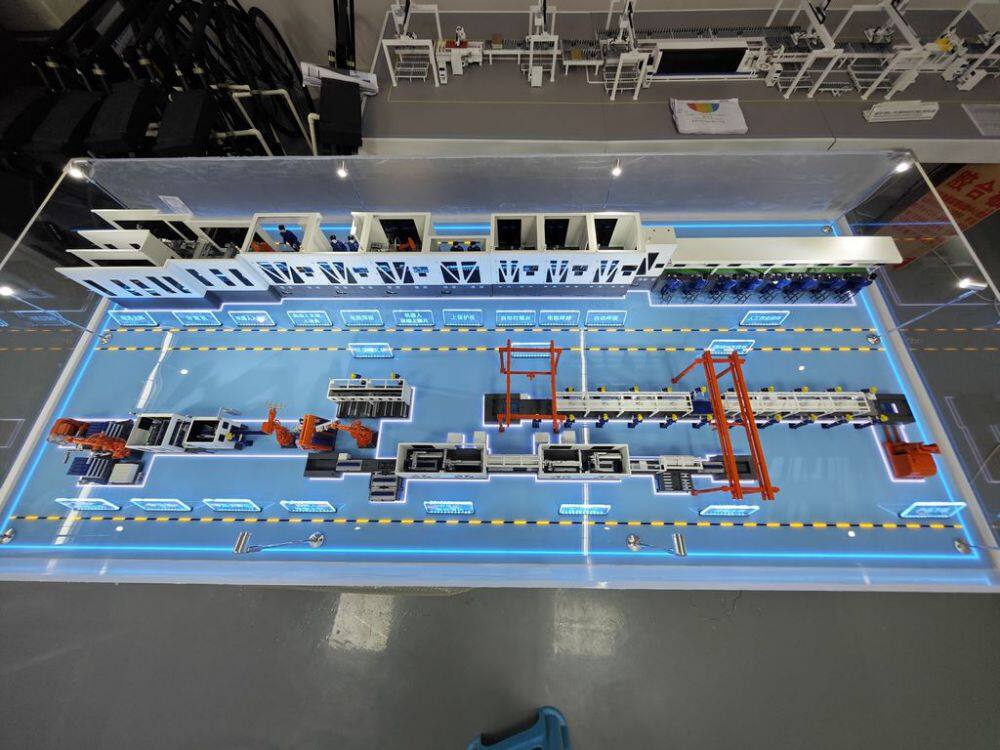

This sandbox adopts a modular layout to present the entire process of lithium battery production, with core display modules including:

Front process area: Display electrode preparation processes such as homogenization, coating, and rolling, with a focus on simulating slurry flow and electrode sheet forming processes

Mid assembly area: including core processes such as winding/laminating, shell welding, etc., dynamically demonstrating the logic of battery cell assembly

Post detection area: key processes such as chemical separation and PACK assembly, simulated battery detection process through lighting system

Intelligent logistics system: AGV car and three-dimensional warehouse linkage, showcasing automatic material distribution system

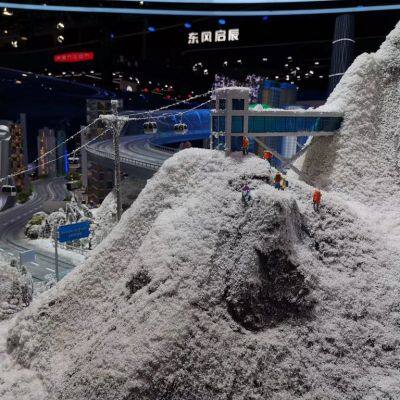

The model is suitable for technical training, scheme demonstration, and exhibition display scenarios by dynamically demonstrating device collaboration, material flow, and data interaction.

2、 Material selection and process implementation

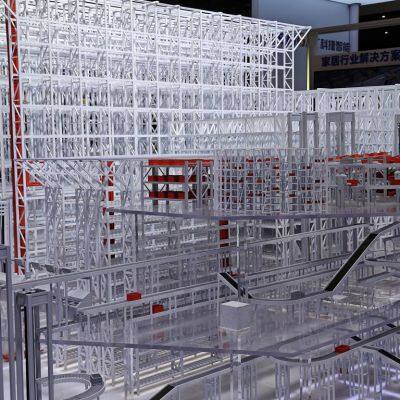

Main structural materials

Framework system: aviation aluminum profiles (main skeleton)+composite wood panels (platform structure), balancing strength and shock absorption requirements

Equipment shell: ABS board (laser cut)+acrylic (transparent observation window), restoring the appearance of industrial equipment

Dynamic component materials

Transmission system: micro reduction motor (conveyor belt)+magnetic guide rail (AGV path)

Fluid simulation: transparent silicone tube (slurry channel)+colored LED light strip (flow effect)

Electronic components: PCB circuit board (control module)+fiber optic bundle (signal transmission visualization)

Special effect implementation

The battery cell winding adopts dual color film layered display

Welding process simulated by high-frequency flashing LED

Use red and green warning lights to distinguish qualified products at the testing station

3、 Production process flow

Precision component machining

Polar film production: using photo cured resin 3D printing coating roller, with a metallic texture sprayed on the surface

Cell model: multi-layer acrylic overlay shows a winding structure, with edge UV printed diaphragm texture

Equipment control panel: etched stainless steel panel+backlit buttons, restore HMI interface

Dynamic System Integration

The conveyor belt adopts a segmented synchronous belt design, and the start stop cycle is controlled by an encoder

The robotic arm uses a servo group and is programmed to perform standard actions of grasping, transporting, and placing

The central monitoring screen plays pre made animations and synchronously displays production data dashboards

Intelligent Interaction Design

Touch screen switches between different production modes (regular/fast charging/low temperature)

Fault simulation system (indicating abnormalities such as material blockage and belt breakage through lights and buzzers)

Material Traceability Demonstration (Scan the QR Code Gun to Activate the Process Flow Playback of Corresponding Cells)

4、 Surface treatment and coloring process

Industrial grade coating scheme

Equipment body: Automotive metallic paint is sprayed in three layers (primer color coat clear coat), with industrial gray (RAL7035) as the main color tone

Pipeline system: distinguished by medium (blue cooling pipeline/red fire pipeline/yellow compressed air)

Warning signs: Reflective stickers for making safety signs, UV printing equipment nameplates

Dynamic effect processing

The welding station adopts strobe LED to simulate arc light

Qualified products are marked with green breathing lamps for inspection

Install rotating warning lights in the fault alarm area

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

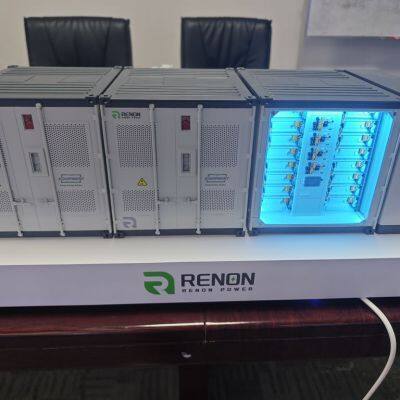

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

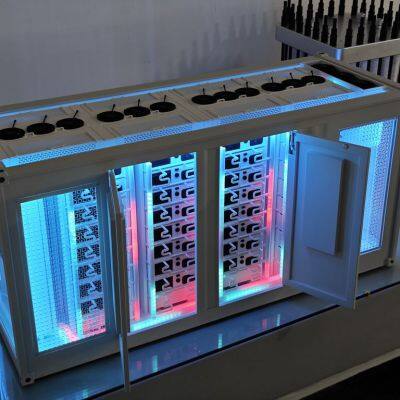

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More