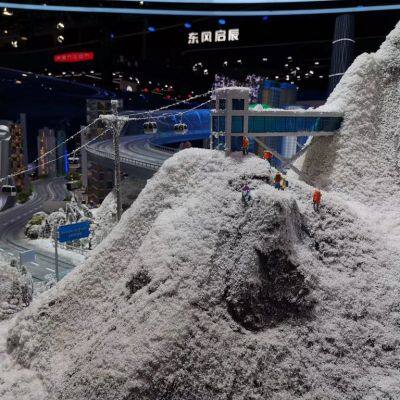

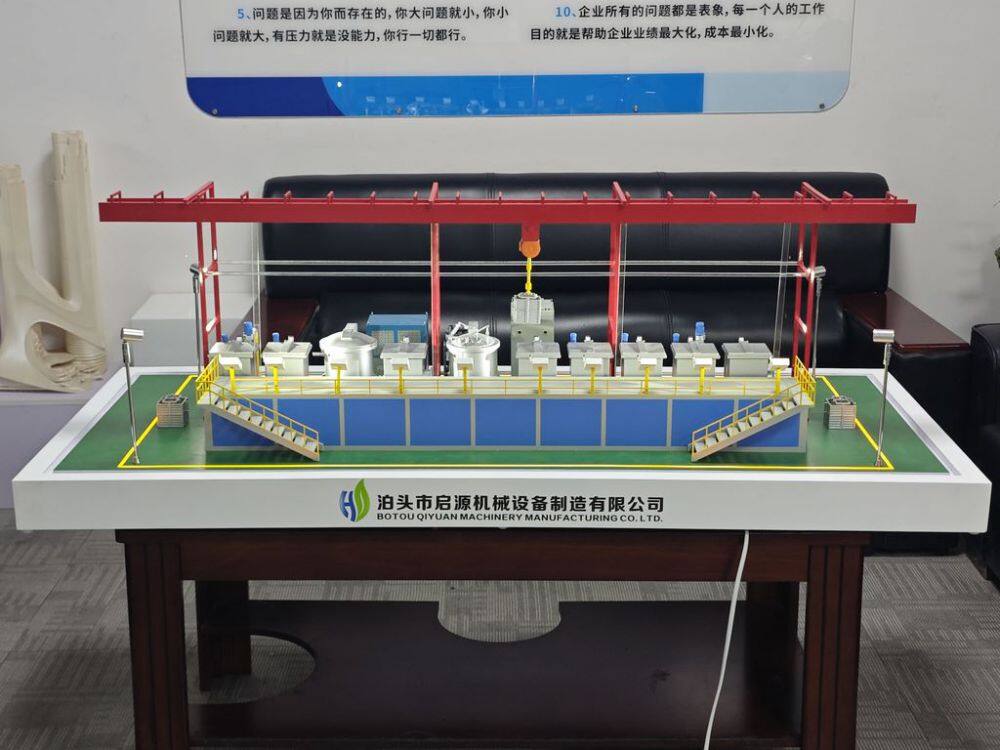

Manufacturer of sand table model for steel plant equipment

Sand table model production plan for steel plant equipment

1、 Model presentation elements and characteristics

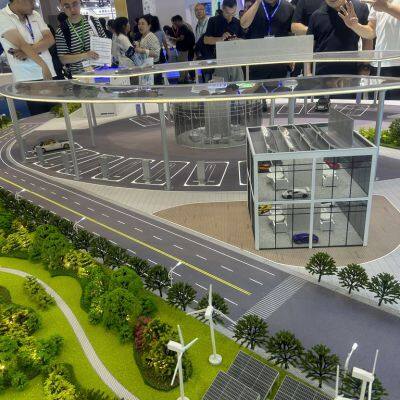

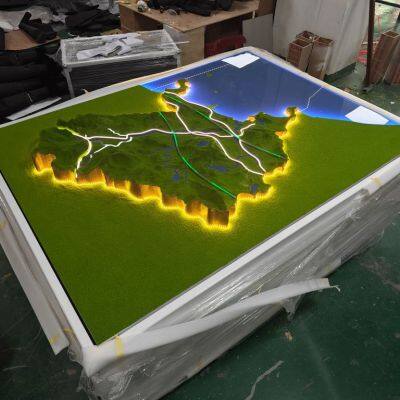

This plan focuses on the three-dimensional display of the entire steel production process, with core display elements including:

Raw material processing area: raw material pretreatment equipment such as stacker reclaimer, dump truck, mixing yard, etc

Ironmaking blast furnace: 1:50 ratio reduction of blast furnace body, hot blast stove, gas purification system

Steelmaking converter: can open and close furnace cover, oxygen lance lifting simulation, steel ladle track

Continuous casting workshop: simulation of crystallizer vibration and demonstration of spray effect in the secondary cooling zone

Rolling production line: dynamic linkage of roughing mill, finishing mill, and coiling machine

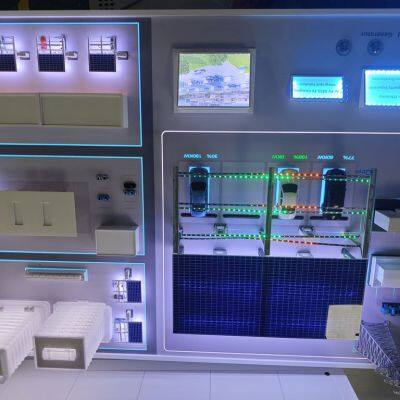

Intelligent control center: LED large screen displays production data and energy efficiency indicators

The characteristic of the model is to dynamically demonstrate the entire process from iron ore to finished materials, which is suitable for enterprise exhibition halls, industry exhibitions, and technical exchange scenarios.

2、 Material selection

Basic structural materials

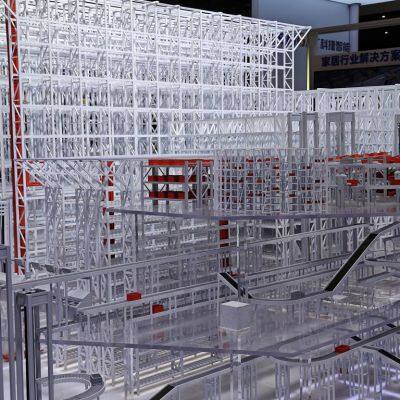

Main frame: aluminum alloy profile (load-bearing structure)+multi-layer plywood (terrain base)

Equipment casing: ABS engineering plastic (CNC machined)+acrylic (transparent observation window)

Metal components: brass wire (pipeline), stainless steel plate (equipment base), aluminum foil (insulation layer performance)

Dynamic System Materials

Micro reduction motor (conveyor belt, coiler)

Magnetic track (steel car operation)

Fiber optic bundle (simulating high-temperature melt flow)

Special effect materials

Transparent resin (steel effect)

Reflective film (metallic luster)

Thermal sensitive coating (temperature change display)

3、 Production process

Precision component manufacturing

3D printing technology: Manufacturing complex structures such as blast furnace cooling walls and converter support rings

Laser cutting: processing large parts such as rolling mill memorial archway and continuous casting roller table

Etching process: making equipment nameplates and safety warning signs

Dynamic System Integration

Liquid simulation system: Micro water pump circulates transparent resin to represent the flow of molten steel

Gas effect: Ultrasonic humidifier simulates gas purification water mist

Lighting control system: segmented control of temperature and color temperature changes of blast furnace hot air (red → orange → yellow)

Intelligent Interaction Design

Touch screen switches between different production modes

Real time display of key parameters such as molten iron composition and rolling temperature

Fault alarm simulation (through light and sound prompts)

4、 Post processing and coloring

Surface treatment technology

Metal paint spraying: using professional color schemes such as industrial gray and high-temperature resistant red

Aging treatment: Charcoal treatment of equipment welds to simulate usage traces

Identification production: using water sticker technology to add equipment numbers and safety signs

Dynamic effect implementation

Breathing light display device in standby mode

Fault alarm red flashing prompt

Temperature sensitive coating color development

Detail enhancement

The cable is made of thin copper wire to increase realism

The operation button adopts a micro switch, which can be actually pressed

The display area uses semi transparent acrylic to simulate LCD effect

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

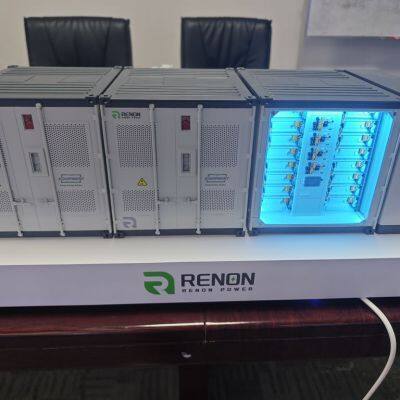

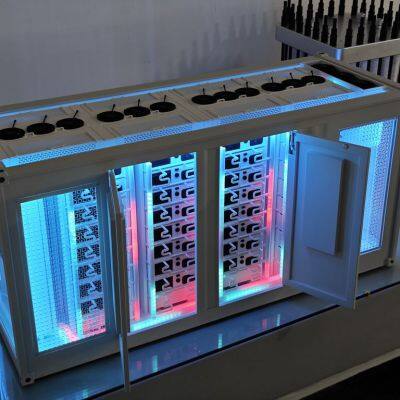

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More