Industrial equipment model manufacturer

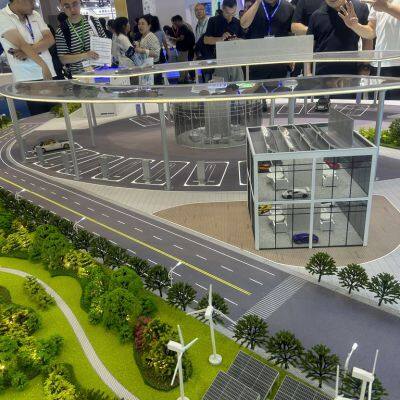

Sand table model making scheme for high-end precision manufacturing production line

1、 Core display elements and characteristics

This plan focuses on the high-end precision manufacturing field, and the core display system includes:

Precision machining unit: core equipment such as five axis linkage machining center, nanoscale grinder, laser engraving machine, etc

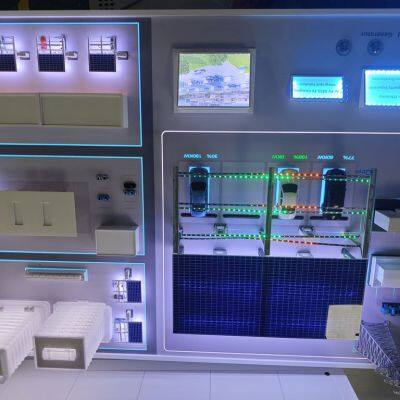

Intelligent detection system: quality control systems such as 3D scanners, spectral analyzers, and microscopic inspection tables

Flexible material flow: AGV intelligent handling, three-dimensional warehousing system, automatic sorting workstation

Digital twin interface: Real time display of device OEE, process parameters, and quality traceability data

The characteristic of the model is to display the entire process of precision manufacturing from raw materials to finished products through dynamic interaction, which is suitable for technology exhibitions, customer demonstrations, and teaching and training scenarios.

2、 Material selection and process design

Main structural materials

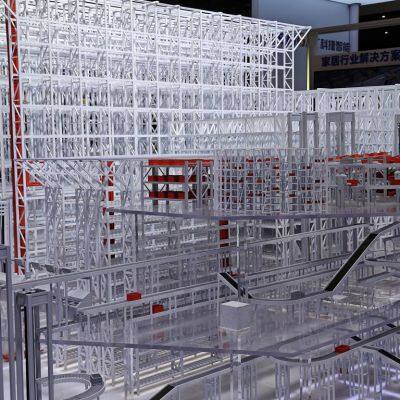

Framework System: Aviation Aluminum Profile (Main Support)+Carbon Fiber Board (Lightweight Components)

Equipment shell: Acrylic CNC engraving (transparent observation window)+metal etching plate (operation panel)

Moving parts: Micro servo motor (robotic arm joint)+Precision guide rail (linear motion module)

Precision component manufacturing process

Micro machining: using micro carving technology to produce micro components such as cutting tools and fixtures

Transparency treatment: Laser cutting of acrylic laminates to display the internal structure of the equipment

Dynamic demonstration: Magnetic levitation technology simulates the effect of spindle rotation

3、 Dynamic System Integration

intelligence control system

Industrial PLC controls the linkage of various equipment

Touch screen switches between different processing modes

Fault simulation system (indicated by lights and sounds)

logistics system

Magnetic navigation AGV car automatic handling

Demonstration of Automated Storage and Access in a Stereoscopic Warehouse

Material Identification System (RFID Simulation)

4、 Post processing and coloring

Surface treatment process

Metallic texture: The equipment casing is treated with electroplating technology

Identification system: laser engraving equipment nameplates and safety signs

Dynamic effect: Fiber bundle simulation machining spark effect

color scheme

Main color scheme: Industrial Grey+Tech Blue

Warning color: Red emergency stop button

Status indication: Three color LED displays the operating status of the device

5、 International Transportation Packaging Solutions

Protective packaging design

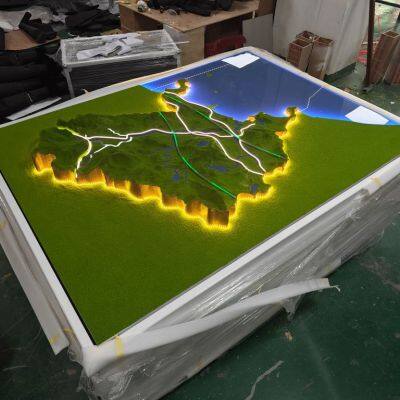

Modular packaging: Independently packaged according to functional zones

Customized buffer: EVA foam trenching and fixing+vacuum adsorption protection

Environmental control: Constant humidity chamber+shock-absorbing sensor

Transportation protection measures

Precision components: shockproof aviation box+inert gas filling

Electronic system: anti-static packaging+electromagnetic shielding

Overall fixation: fixing the angle steel frame inside the container

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

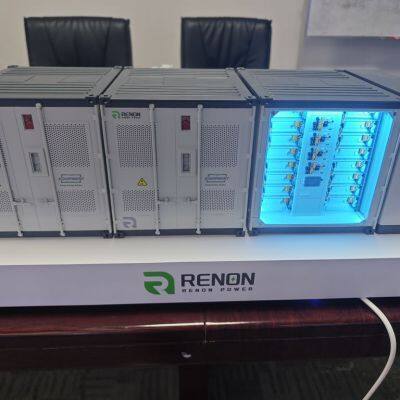

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

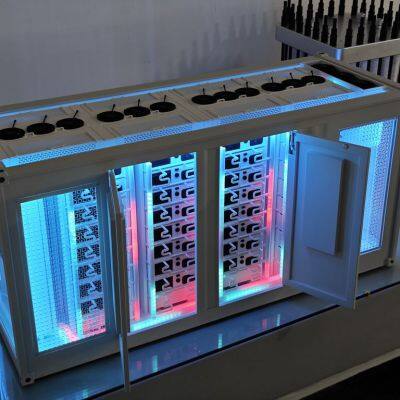

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More