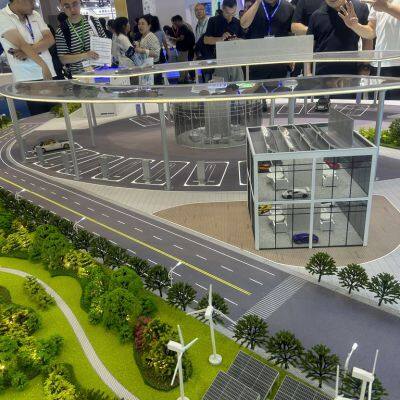

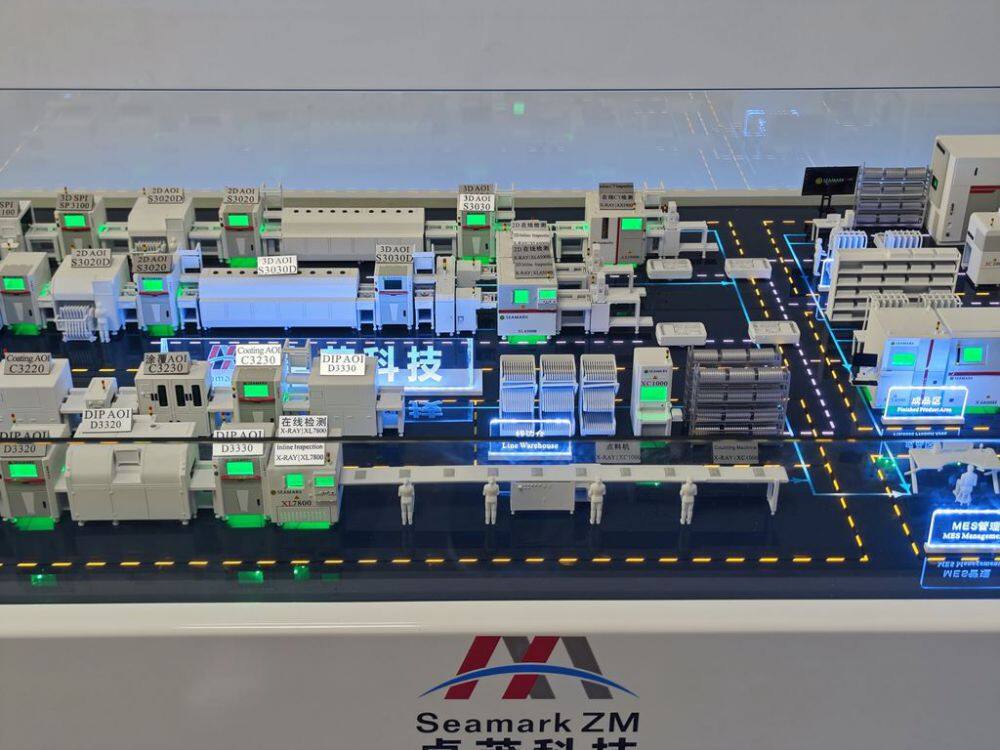

Sand table model for industrial automation production line

Sand table model making scheme for industrial automation production line (in the field of electronic manufacturing)

1、 Model presentation elements and characteristics

This program focuses on intelligent manufacturing demonstrations in the field of electronic manufacturing, with core display elements including:

SMT SMT SMT production line: showcasing core equipment such as high-speed SMT machines, solder paste printing machines, reflow soldering furnaces, etc

DIP plug-in line: including traditional process links such as wave soldering machine, plug-in machine, and testing station

Intelligent detection system: AOI optical detection equipment, X-ray detector and other quality control systems

Intelligent warehousing and logistics: logistics links such as AGV carts, three-dimensional warehouses, automatic sorting systems, etc

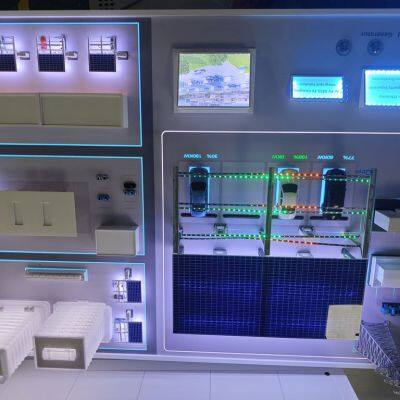

Central control panel: dynamically displays production data, equipment status, and material flow status

The characteristic of the model is to display the entire process of electronic manufacturing through dynamic interaction, which is suitable for enterprise technology display, industry exhibitions, and educational training scenarios.

2、 Material selection

Basic structural materials

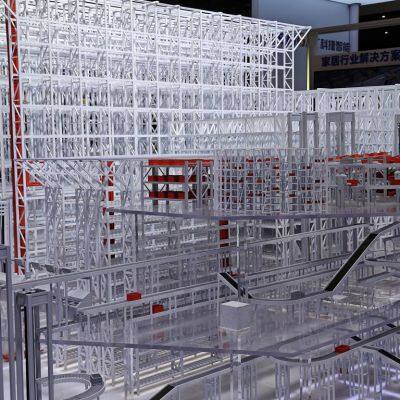

Frame material: aluminum alloy profile (main frame)+oak board (auxiliary structure), balancing strength and processing convenience

Base material: high-density foam board (lightweight shock absorption)+wooden veneer (beautiful and durable)

Equipment model materials

Main structure: ABS plastic sheet (CNC carved)+acrylic (transparent component)

Metal textured components: 0.3mm brass sheet (small parts)+aluminum plate (large equipment casing)

Dynamic components: Micro stepper motor (conveyor belt), magnetic control sensor (automatic door), LED light strip (workspace lighting)

Special effect materials

Fiber optic materials (analog circuit signal transmission)

Transparent resin (displaying the internal structure of the device)

Magnetic powder (simulating electromagnetic field effect)

3、 Production process

Precision component manufacturing

3D printing technology: used for making micro precision components such as surface mount machine nozzles and PCB boards

Laser cutting: Processing flat parts such as acrylic protective covers and metal partitions

CNC engraving: making complex curved parts such as equipment casings and operation panels

Dynamic System Integration

Conveyor belt system: using micro motors to drive rubber belts, simulating material flow

Robot arm demonstration: Simplify the robotic arm using servo control and demonstrate grasping actions

Lighting control system: Program control LED light strips to simulate equipment operation status

Intelligent Interaction Design

Touch screen switches between different production modes

Real time display of production pace, yield rate, and other data

Abnormal alarm system simulation (prompted by lights and sounds)

4、 Post processing and coloring

Surface treatment technology

Metal paint spraying: using standard colors such as industrial gray and equipment blue, spraying in three layers (primer color paint protective paint)

Aging treatment: lightly polish the edges of the equipment to simulate usage marks

Identification production: Using water sticker technology to add equipment nameplates and safety signs

Dynamic effect implementation

Flow light effect simulates production rhythm

Breathing light display device in standby mode

Fault alarm red flashing prompt

Detail enhancement

The cable is made of thin copper wire to increase realism

The operation button adopts a micro switch, which can be actually pressed

The display area uses semi transparent acrylic to simulate LCD effect

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

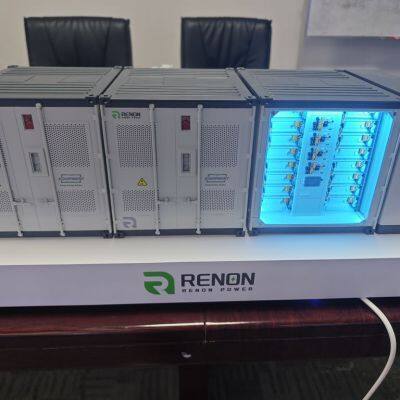

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

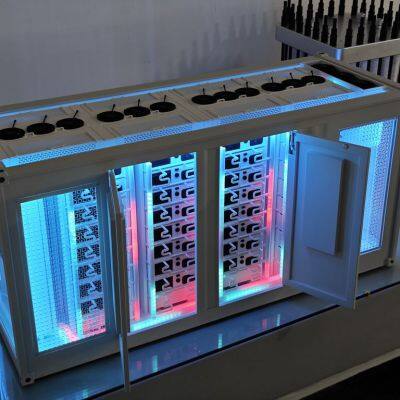

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More