Industrial park model manufacturer

1、 Project positioning and characteristics

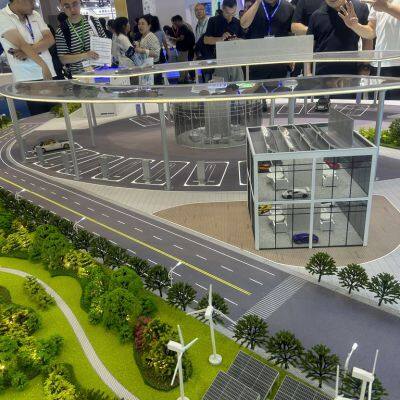

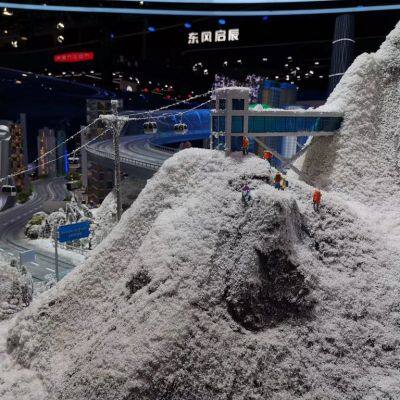

This plan is based on the core concept of "integration of industry and city", and uses a 1:150 scale to restore the panoramic view of the industrial park, highlighting three major features:

Function visualization: distinguish modules such as production area, logistics area, and R&D center

Dynamic demonstration: Integrated lighting system simulates production process

Ecological elements: Retain 20% of the park's green belt configuration

2、 Core manufacturing process

(1) Infrastructure construction

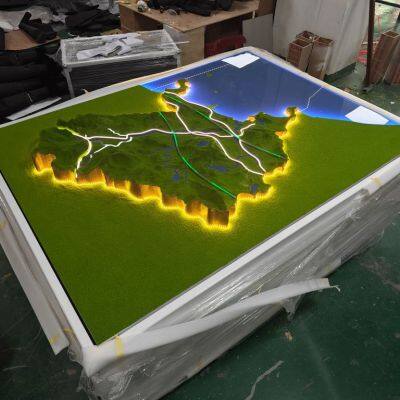

Terrain shaping

Use high-density foam board to carve topographic relief

Transparent water pattern effect cast with epoxy resin in river areas

Pre embedded magnetic tracks on the main road facilitate the replacement of vehicle models in the later stage

Architectural complex production

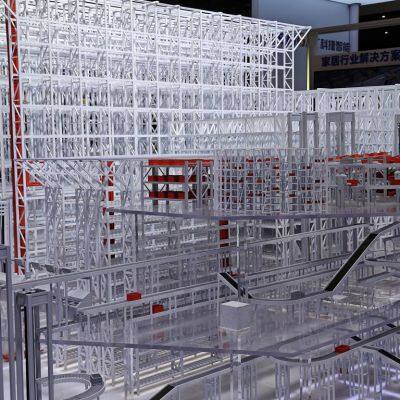

The factory adopts ABS board laser cutting and splicing

Glass curtain wall buildings use 3mm acrylic board UV printed texture

Special structural components (such as chimneys and cooling towers) are 3D printed

(2) Detail Enhancement System

Industrial facility restoration

Pipeline system: aging treatment of copper pipes with different diameters

Tank area: Metal paint spraying combined with rust stain effect

Loading and unloading platform: adding micro hydraulic devices to simulate lifting and lowering

Environmental Creation

Green belt: electrostatic grass planting technology combined with miniature tree species

Pedestrian walkway: laser engraved tile texture

Vehicle model: Customized printing factory specific transport vehicle

3、 Color and Light and Shadow Engineering

Standardized coating system

Architectural complex: Industrial gray (Pantone Cool Gray 9C) as the main color tone

Ground: Matte asphalt effect paint layered spraying

Warning sign: Fluorescent orange accents in key areas

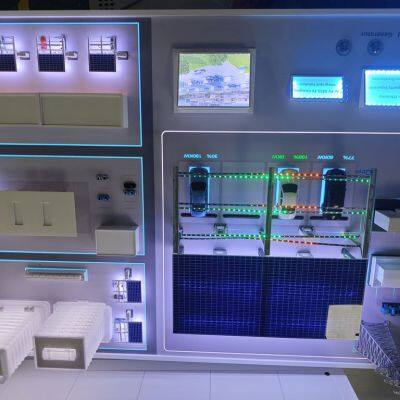

Intelligent Light System

Production area: Warm yellow light simulation workshop lighting

Road: Embedded LED simulated street lighting

Dynamic demonstration: Arduino controls light flow effect

4、 Quality control nodes

Proportional verification: Conduct weekly 3D scanning comparison

Color management: Establish a dedicated color card library

Safety test: 72 hour continuous power on experiment

5、 Delivery standards

Main structure error ≤ 0.5mm

Dynamic system response time<0.3 seconds

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

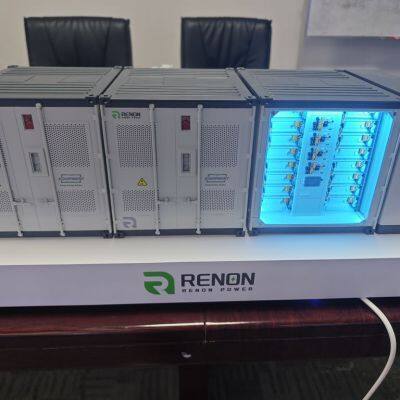

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

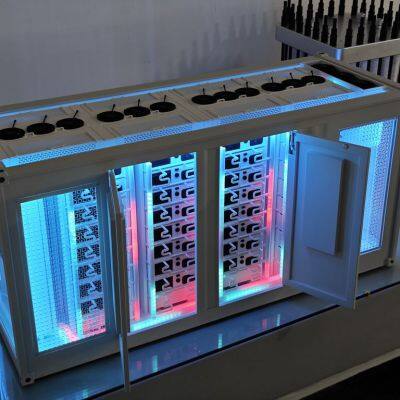

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More