Port construction model customization factory

Sand table model production plan for port construction

1、 Project Overview

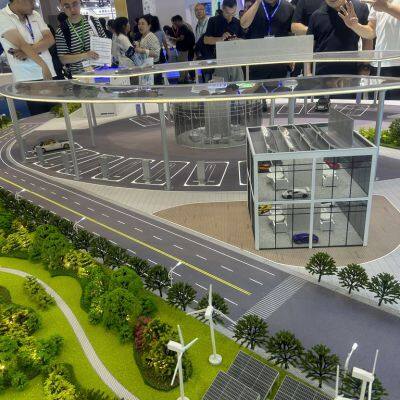

This plan aims to restore a modern container port at a ratio of 1:150, with a focus on three major functional areas: terminal operation area, warehousing and logistics area, and ship berthing area. By using dynamic lighting systems and micro mechanical structures to simulate core operational processes such as lifting and transportation, we ensure that the model accuracy reaches over 90%.

2、 Production process flow

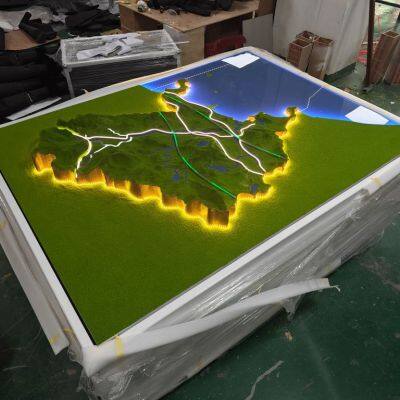

1. Construction of topographic base

Bottom plate treatment: 5mm thick PVC board is used as the foundation, and the contour of the coastline is laser engraved to ensure smooth edges.

Water production: Double layered blue acrylic panels are stacked, with optical fibers laid in the middle to simulate dynamic waves, and the edges are sandblasted to reduce reflection and enhance realism.

Ground shaping: Use epoxy resin to shape the texture of the dock floor, combined with fine sand and gypsum powder to simulate different materials (such as concrete and asphalt).

2. Production of core facilities

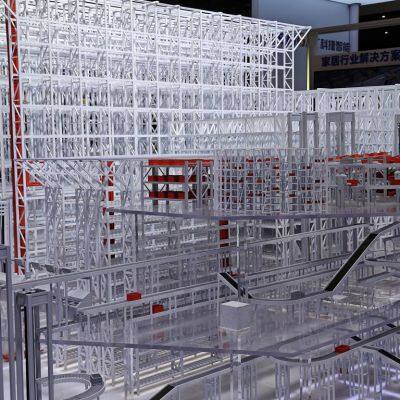

(1) Container crane

Material selection: ABS sheet is used to construct the main structure, and metal bearings ensure flexible joint rotation.

Process key points: 3D printing of key connecting components, magnetic suction design of the lifting arm for easy disassembly and angle adjustment.

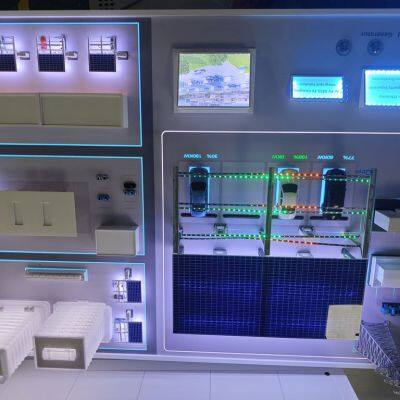

(2) Storage yard and storage area

Shelf construction: Acrylic grating laser cutting to ensure precise spacing between storage locations.

Container production: The mini container is made of ABS injection molding, with the company logo printed on the surface to enhance the authenticity of details.

(3) Ship model

Hull making: Resin flip casting, assembled in pieces to ensure smooth curves of the hull.

Detail processing: The deck is etched with anti slip patterns, and accessories such as ship anchors and cables are handmade with copper wire.

3. Dynamic system integration

Rail transportation system: Based on N-scale train model modification, magnetic induction tracks are laid to achieve automatic round-trip of container transport vehicles.

Lighting control system: PLC programming controls tower crane operation lights, ship signal lights, and dock lighting, simulating day and night work scenarios.

3、 Artistic processing and detail enhancement

1. Color system

Industrial Zone: The main color scheme adopts cool gray (Pantone Cool Gray 11C), paired with orange safety signs, highlighting the industrial atmosphere.

Natural landscape: Gradual spray paint is used in the mudflat area, and the vegetation is decorated with pastel to simulate the real ecological transition.

2. Detail optimization

Cable tie post: Hand bent 0.3mm copper wire to restore the true proportion.

Container rust: Salt etching technique is used to partially age and enhance the traces of use.

Ground effect: Stain solution simulates oil stains, dry sweeping highlights the worn area.

4、 Quality Control and Acceptance Standards

Stage acceptance

Terrain shaping completed: Check the smoothness of the coastline and ground texture.

Facility assembly completed: testing mechanical structural stability (such as bridge crane rotation, track operation).

Dynamic debugging completed: Verify the synchronization between the lighting logic and the transportation system.

Tolerance standard

Building verticality deviation ≤ 0.5 °

Track parallelism error<1mm

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

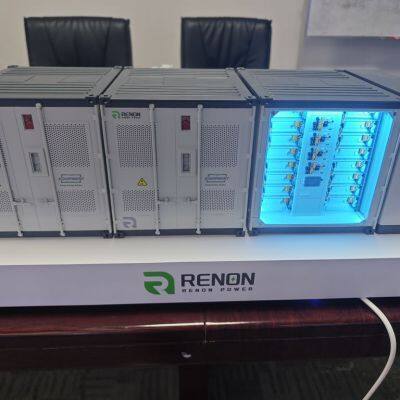

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

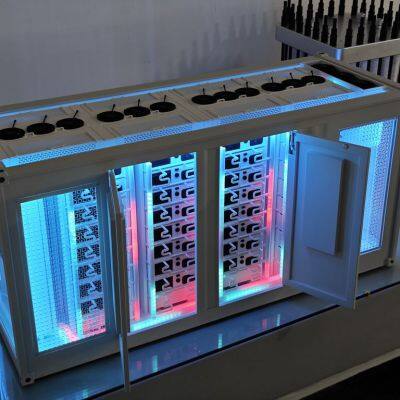

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More