Packaging material sand table model manufacturer

1、 Project positioning and characteristics

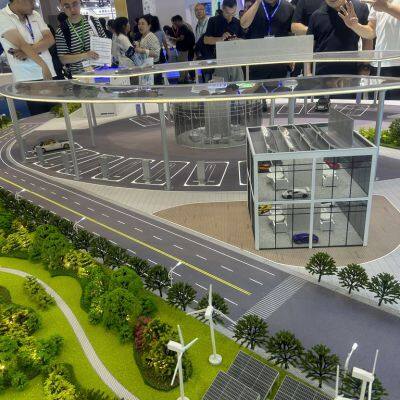

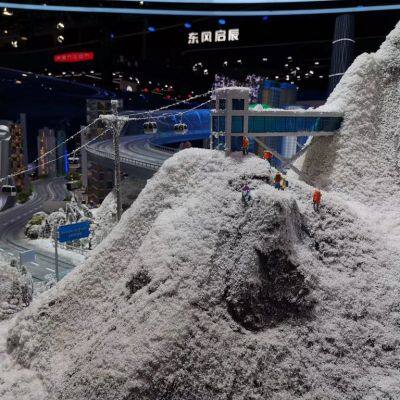

This plan constructs an intelligent packaging material display sand table at a scale of 1:50, and dynamically decomposes the structure to display the application scenarios of new materials such as corrugated paper, bio based plastics, and biodegradable films. The model includes three major modules: raw material processing, molding and processing, and warehousing and transportation. It adopts a magnetic replaceable design to achieve 90% industrial scene restoration.

2、 Core production process

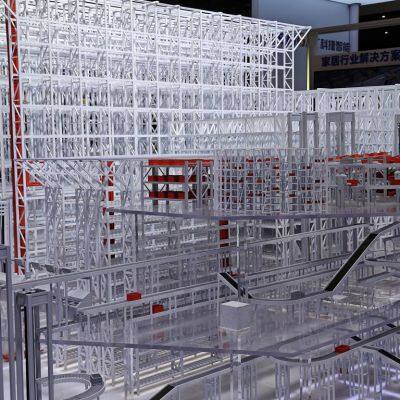

1. Layered base construction

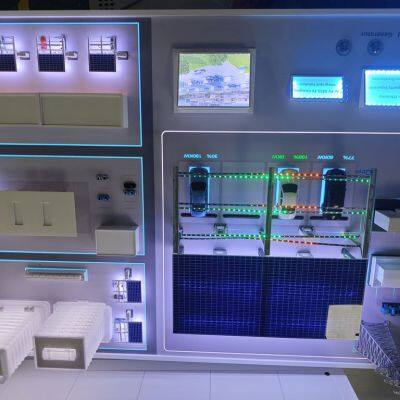

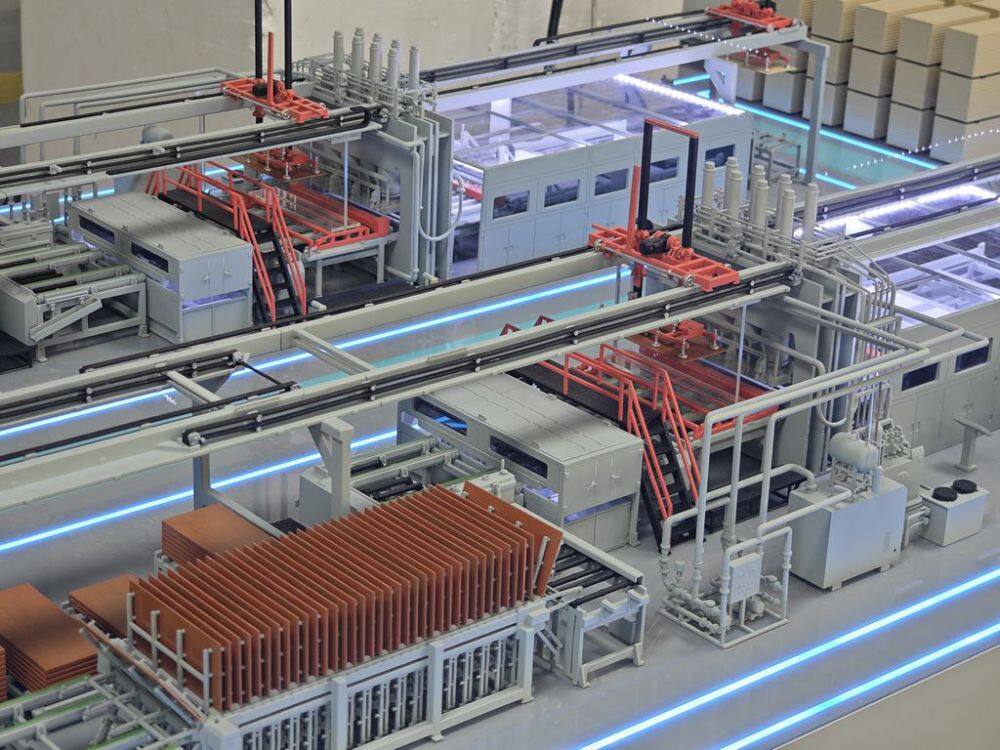

Intelligent baseboard system: 5mm aviation aluminum plate as the load-bearing layer, embedded LED matrix display material characteristic data

Scene zoning: Laser carved acrylic partitions are divided into raw material area (wood pulp/starch granules), production area (hot pressing equipment), and finished product area (e-commerce packaging boxes)

Dynamic conveyor belt: Micro stepper motor drives transparent PETG conveyor belt, showcasing the processing flow of packaging materials

2. Material performance and craftsmanship

Corrugated cardboard restoration:

Using 0.3mm oak veneer laminated molding, UV printed macro texture

Removable cross-section display with seven layers of corrugated structure and embedded fiber optic lighting

Bioplastic simulation:

Epoxy resin mixed color paste pouring, adding matting agent to eliminate reflection

Production of PLA vacuum formed trays using hot forming technology, with degradation and oxidation effects applied to the edges

Intelligent packaging components:

3D printed NFC chip shell, triggered by linkage with the sensing area of the base plate, instructional video

3. Integration of interactive systems

AR recognition module: Paste Vuforia recognition image on the finished product packaging box, scan and display carbon footprint data on the mobile end

Environmental simulation device: Micro atomizer simulates a humid environment and compares the differences in weather resistance of different materials

Mechanical testing demonstration: Micro hydraulic rod applies pressure to the sample, and the digital tube displays real-time load-bearing data

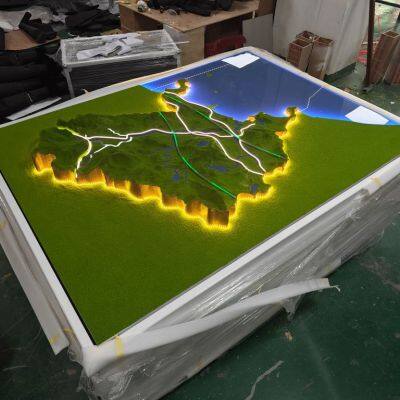

3、 Visual enhancement scheme

Color management system:

The raw material area adopts Pantone 14-0443TCX (bamboo green) to emphasize environmental protection properties

Mechanical components use RAL 7035 (light gray) to reduce visual interference

Dynamic identification system:

Magnetic levitation tag display material parameters

UV ink printing hidden recycling label

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

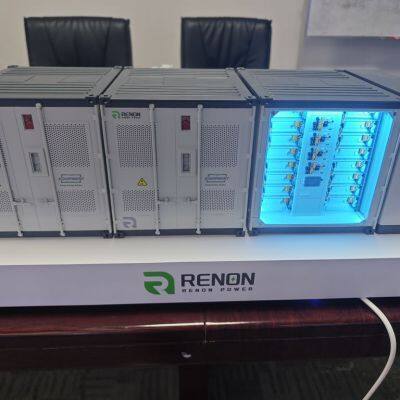

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

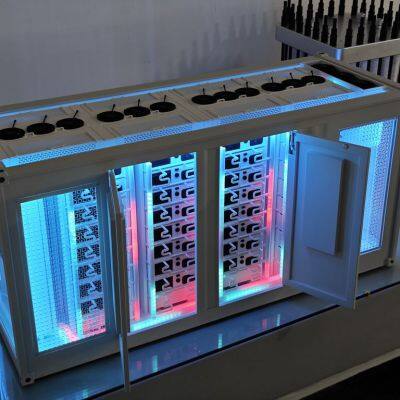

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More