Precision equipment model customization manufacturer

1、 Project positioning and technical roadmap

This plan adopts a dual presentation method of "structural anatomy+dynamic demonstration" to reproduce a certain type of precision CNC machine tool at a scale of 1:25. Through modular disassembly design, the core components such as the spindle transmission system, guide rail feed mechanism, and tool magazine are highlighted, and basic actions such as spindle rotation and tool magazine tool change are synchronously simulated.

Core production indicators

Static restoration degree ≥ 92% (based on 3D scanning comparison)

Dynamic system failure rate<0.5 times/demonstration cycle

Interactive components account for over 40%

2、 Implement the process in stages

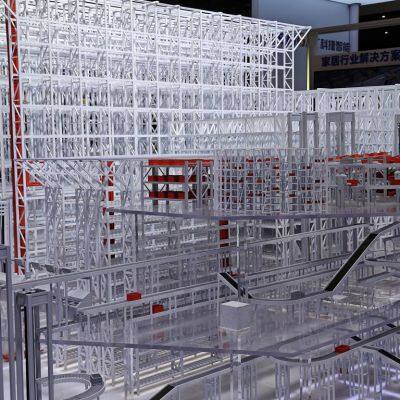

1. Precision casting stage

Metal skeleton forming: The brass base is cast using the lost wax method, and the flatness error is ensured to be ≤ 0.02mm through CNC precision milling

Application of composite materials:

Guide rail system: chrome plated aluminum oxide ceramic treatment

Protective cover: 0.5mm acrylic vacuum hot bending formed

Operation panel: UV printed imitation metal brushed texture

2. Mechanical transmission system

Micro harmonic reducer: 3D printed planetary gear set (module 0.3)

Linear module: self-made cross roller guide rail, matched with 0.15mm stainless steel ball holder

Pneumatic components: Integrated solenoid valve control with a Φ 2mm miniature cylinder

3. Surface finishing

Etching process: Chemical etching of nameplates and dials (minimum line width 0.1mm)

Multi layer spraying:

Primer: Epoxy resin conductive coating

Topcoat: two-component polyurethane matte paint

Protective layer: Nano scale oil repellent coating

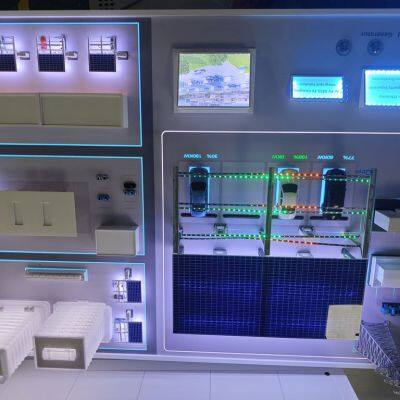

3、 Dynamic System Integration

1. Electromechanical control system

Main control unit: STM32F407 core board

Sensor network:

Hall element detects spindle speed

Micro photoelectric switch positioning knife magazine

Strain gauge monitoring cutting simulation load

2. Human computer interaction design

7-inch capacitive touch screen embedded in console

Tri color LED working condition indicator light group

Physical emergency stop button (with self-locking function)

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

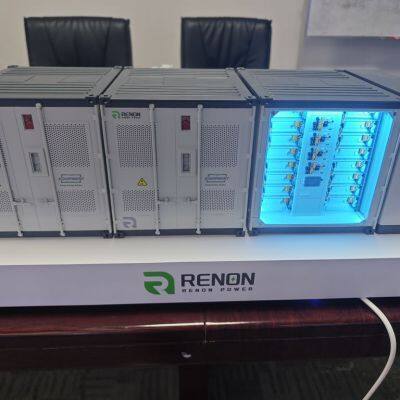

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

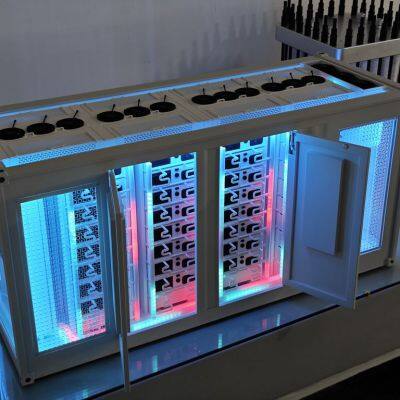

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More