Heavy duty machine tool equipment model manufacturer

Case study of making miniature models of heavy-duty machine tools

1、 Project Overview

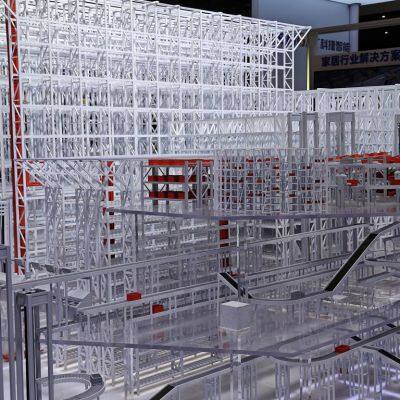

This project aims to create a 1:20 scale miniature model of a heavy-duty machine tool, with a focus on reproducing the main structure, transmission system, and operating units of the machine tool. The model is about 60 centimeters long and adopts a production scheme of "metal body+precision details", pursuing a 90% restoration degree and highlighting the precision and power of industrial equipment.

2、 Material selection and main production

The bed is made of gray cast iron and undergoes precision machining to ensure flatness and stability. The guide rail is made of quenched steel bars that are finely ground to ensure smoothness and flatness. The spindle box adopts aluminum alloy CNC machining, with reserved counterweight space inside. The base is made of solid cast iron, effectively reducing the center of gravity.

3、 Main component production

Bed body: bolted connection after segmented casting, with scraping and grinding treatment at the joints

Guide rail: precision grinding after surface quenching treatment, manual scratching of installation surface

Spindle: Made of stainless steel precision machining, with tapered holes ground and processed

Knife tower: precision cast brass, each blade can rotate independently

4、 Detail processing technology

Operation panel: buttons and display screen details are made using etching technology

Lubrication system: Copper tube bent, oil cup made of transparent resin

Protective cover: Acrylic sheet hot bent, metal edging treatment

Inscription on the sign: using micro carving technology, the text is clear and recognizable

5、 Painting process flow

Adopting a specialized coating scheme for industrial equipment:

Surface treatment: sandblasting rust removal, phosphating treatment to enhance adhesion

Primer spraying: Epoxy primer is sprayed as a whole and cured by high-temperature baking

Main color coating:

Bed spraying machine ash

Moving parts maintain their original metallic color

Spray warning colors on hazardous areas

Identification restoration: The nameplate adopts metal etching and painting process

6、 Aging and texture expression

The guide rail surface retains its metallic color and is sprayed with rust proof oil

Frequently perform slight wear treatment on the operating parts

Traces of residual liquid sprayed in the coolant tank

Slight rusting effect on the grounding area

7、 Implementation of movable functions

The spindle can be manually rotated

Skateboards can move along the guide rails

The turret can rotate with adjustable degrees

Tailstock can be adjusted forward and backward

8、 Quality requirements

All joint surfaces are tightly sealed

The moving parts run smoothly

Uniform and flawless coating

Accurate restoration of details

9、 Project Features

Using real machine tool materials and processes

Realize movable function in key areas

Surface treatment restores industrial texture

Striving for excellence in detail production

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

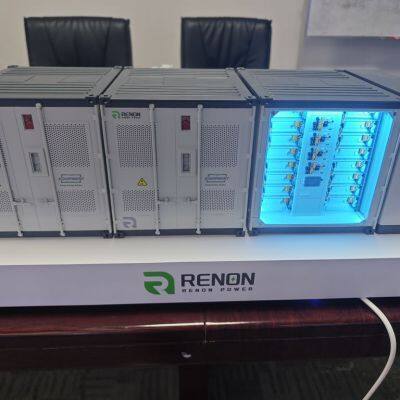

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

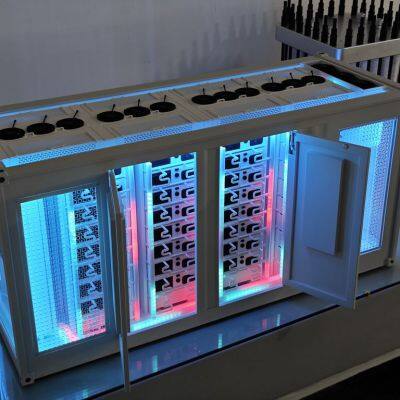

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More