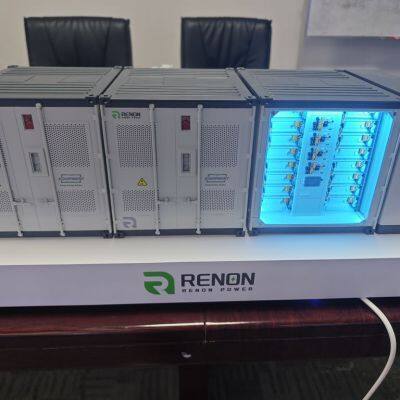

Manufacturer of energy storage cabinet model

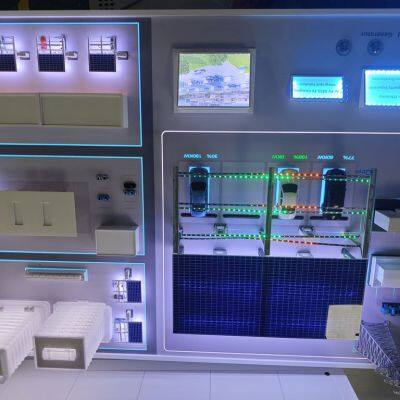

Case study on the production of miniature models of energy storage containers

1、 Project Overview

This project aims to create a 1:20 scale energy storage container model, with a focus on restoring the appearance features, heat dissipation system, safety devices, and interface units of a standard container. The model is about 80 centimeters long and adopts a structural scheme of "metal frame+composite panel skin", pursuing a 90% restoration degree, highlighting the practicality and professionalism of industrial equipment.

2、 Material selection and main production

The frame is constructed with aluminum alloy profiles to ensure structural stability. The wall panel is made of ABS laminates and filled with lightweight foam to maintain heat insulation performance. The bottom plate is made of fiberglass plate, with anti slip texture on the surface. The top of the box is made of stainless steel plate to restore the real drainage structure.

3、 Main component production

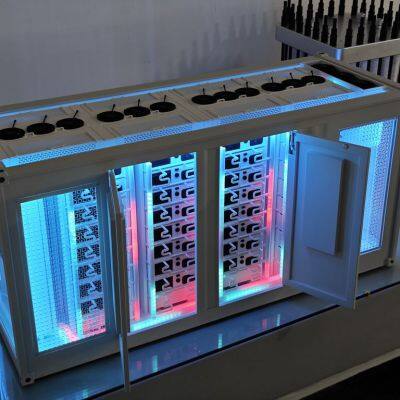

Box structure: adopting modular design, six sides can be independently disassembled

Ventilation system: Rainproof louvers are made of etched sheets, and the mesh holes are accurately restored

Cable interface: Copper interface component, protective cover can be opened and closed

Lifting angle piece: made of cast steel, surface treated with rust prevention

4、 Detail processing technology

Box texture: The unique corrugated board effect of the container is pressed through the mold

Door lock mechanism: precision cast brass, door bolt can be operated in practice

Warning sign: Using screen printing technology, the text is clear and durable

Grounding device: Copper grounding post, details fully restored

5、 Painting process flow

Adopting the standard coating scheme for industrial containers:

Surface treatment: overall sandblasting, epoxy primer spraying

Main color coating:

Box spraying standard container green

Top spray insulated white coating

Bottom frame sprayed with rust proof dark gray

Color separation processing: precise masking and spraying of door frames, corner pieces, and other parts

Identification production: Box number and warning signs are made using water sticker technology

6、 Aging and texture expression

Spraying muddy splash effect on the bottom of the box

Wear and rust treatment on corner parts

The door lock mechanism shows signs of use

Slight fading at the top indicates sun aging

7、 Special effect processing

Three dimensional performance of cooling fan grille

Restoration of internal structure details of cable interface

The waterproof sealing strip is made of soft rubber

Box corner number stamped process restoration

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More