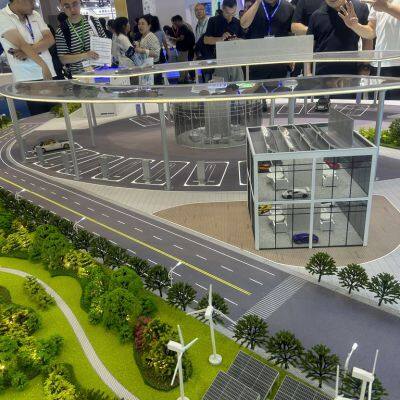

Manufacturer of sand table model for chemical industrial park

Case study of sand table model production in chemical industrial park

1、 Project Planning and Design

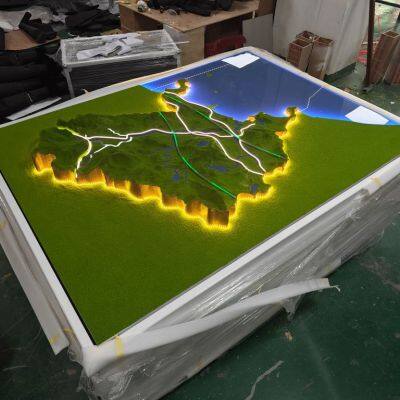

This project produces a 1:200 scale panoramic sand table model of a chemical industrial park, with a total area of approximately 4 square meters. The focus is on showcasing the factory planning, pipeline layout, equipment clusters, and supporting facilities, adopting a "layered construction+modular assembly" solution, pursuing a 90% restoration degree, highlighting the professionalism and complexity of the chemical industrial park.

2、 Base and terrain fabrication

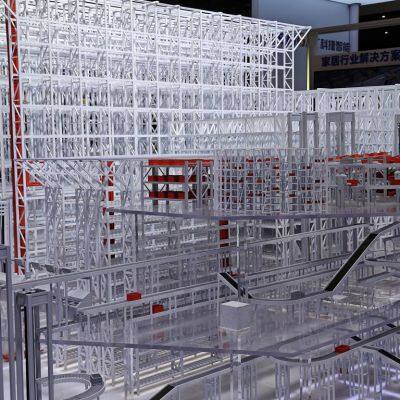

The base adopts a light steel keel frame and is covered with 18mm anti deformation composite board. Terrain molding uses high-density polystyrene foam board to carve flat foundation and gentle slope terrain through hot wire cutter. The road network adopts precise cutting and laying of PVC boards, and the curbstones are made of ABS strips.

3、 Construction and Facility Manufacturing

Factory building: ABS board laser cutting assembly, wall etched with industrial building texture

Reaction device: Welding combination of stainless steel pipes, displaying complex process pipelines

Tank area: Aluminum alloy vehicle made storage tanks of various specifications, with guardrails made of etched sheets

Pipe gallery system: Copper pipe bending main pipe gallery, support 3D printed into shape

4、 Detail craftsmanship processing

Pipeline identification: using water transfer printing technology to restore the flow direction mark of the medium

Equipment details: Small equipment such as pumps and valves are cast with resin

Safety facilities: complete presentation of safety equipment such as fire hydrants and eye wash stations

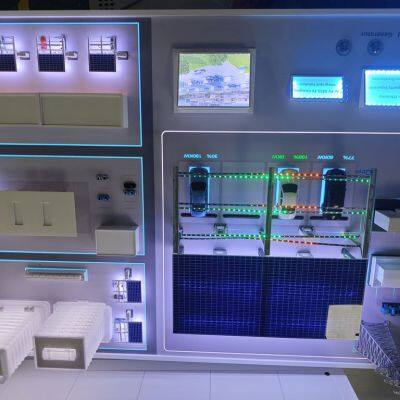

Lighting system: LED fiber optic system simulates the lighting effect in the factory area

5、 Painting process flow

Adopting industrial grade coating standards:

Bottom treatment: All components are sprayed with gray primer

Architectural Painting:

The factory adopts a light gray color scheme

Use blue and white color scheme in the office area

Spraying warning colors in hazardous areas

Equipment coating:

Tanks are colored according to their medium classification

Pipelines are separated by medium type

The equipment foundation is made of concrete color

6、 Special effect processing

Corrosion treatment for pipeline supports

The effect of making oil stains on the ground

Performance of anti-seepage treatment in tank area

The green belt adopts electrostatic grass planting technology

7、 Lighting system configuration

Install hazard warning lights in the device area

Road system layout, street lamp lighting

Office building simulation indoor lighting

Chimney exhaust effect setting

8、 Restoration of Safety Signs

Warning signs are screen printed

Stereoscopic production of directional signs

Restoration of equipment nameplate details

Clear safety channel markings

9、 Overall layout and integration

Arrange equipment positions according to the process flow

Reserve sufficient maintenance space

The road network meets fire safety requirements

Reasonable arrangement of green isolation belts

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

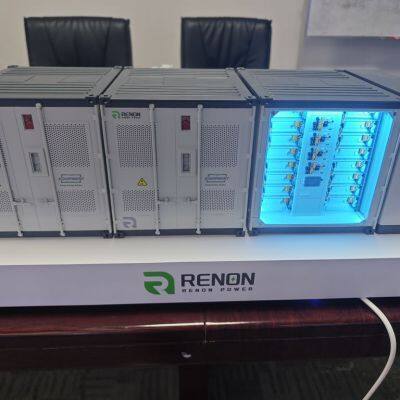

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

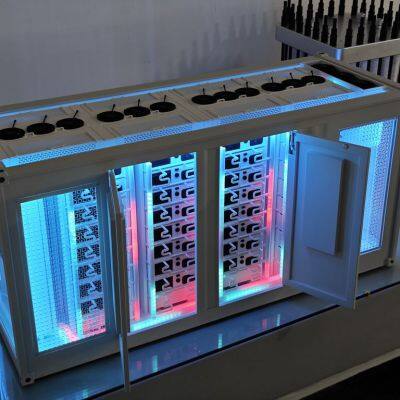

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More