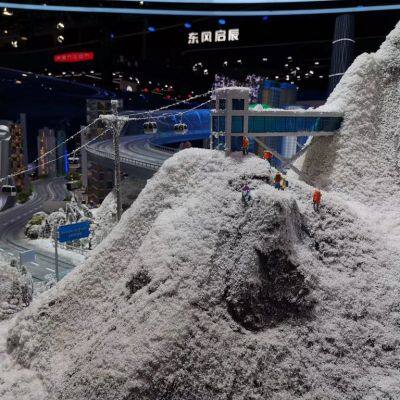

Steel plant model making factory

Steel Plant Model Making: Realistic Reproduction of the Industrial Landscape

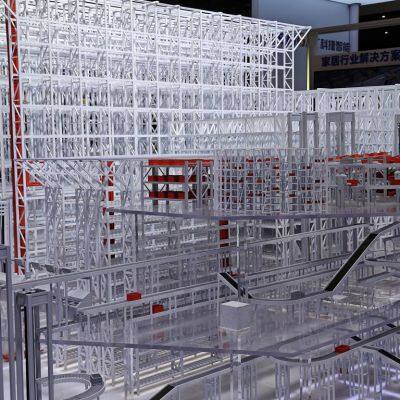

This time, a 1:100 scale steel plant model was made based on the hot rolling workshop of a medium-sized steel plant, with a target restoration rate of over 90%. From material selection to post production aging, the entire process revolves around the "real texture of industrial scenes". The following is a practical record of the core steps.

1、 Material selection: balance between practicality and simulation

Model materials need to balance processing difficulty and visual credibility:

Factory frame: Select 2mm thick PVC board, which has good toughness, is easy to cut, and can simulate the tough lines of steel structures; After aging treatment, the red paint surface can restore the iconic anti rust paint texture of the steel plant.

Core equipment (blast furnace, converter, rolling mill): Resin clay molding for blast furnace (flexible shaping of conical and curved structures), polishing and shaping after drying; The main body of the converter is sprayed with silver paint, and some areas are painted with dark red to simulate high-temperature oxidation spots; Small components such as rolling mill gears are 3D printed, and after printing, gradient polishing (200 mesh → 1000 mesh) is used to eliminate layer patterns.

Pipeline system: PVC pipes are used to distinguish the medium (yellow=steam, blue=cooling water, silver=material), supplemented with fine copper wires as supports to simulate suspended support, which is low-cost and easy to shape.

Ground and foundation: Cast with gypsum and green pigment, dry and polish to create cement cracks, then sprinkle "talcum powder+brown pigment" to simulate dust accumulation, replacing expensive epoxy resin floor models.

2、 Production process: Fine replication of individual components

one

Building of factory structure:

First, use wooden strips as internal keels to enhance stability, and then cover with PVC boards. When cutting, use a utility knife and ruler to ensure straight edges. Use hot melt adhesive to quickly fix the connection between the beam and column, and then apply white latex for toughening after it is firmly secured. To simulate the "welding marks" of steel structures, lightly scratch the dents at the junction of beams and columns with a carving knife, spray gray paint, and then wipe off the edges to create an industrial feel of "paint peeling and exposed bottom".

two

Equipment shaping:

Blast furnace: resin clay is piled up to form a cone-shaped main body, and the top is thickened to make a "furnace top platform". After drying, a surgical knife is used to repair the depression of the maintenance door.

Converter: Silver self painted base, with a copper wire bent and welded bracket at the bottom to enhance the three-dimensional effect, and locally overlaid with dark red simulated oxidation spots.

Rolling mill "roller": ABS pipe cutting section bonding, surface coated with metal foil, restoring steel luster under light and shadow.

three

Pipeline system assembly:

Pre arrange the direction according to the workshop layout, and insert toothpicks to fix the angle during hot melt adhesive bonding (steam pipe tilted, material pipe horizontal). Spray the base color on each section of the pipeline first, and use cotton swabs to blend the paint at the interface to simulate the penetration of long-term stains.

3、 Post processing: soul injection of aging and details

The "liveliness" of the model comes from later aging:

Coloring stage:

Spray red matte paint on the steel frame of the factory building first, and when it is half dry, lightly sweep the edges and bolt holes with gray paint to simulate rusting and paint peeling; The main body of the equipment is sprayed with silver ash, and deep ash is stacked in the shadows. The top of the converter gradually turns dark red; After spraying the medium color on the pipeline, lightly sand the interface with sandpaper to expose the underlying color and cause wear.

Aging and strengthening:

Spray matte protective paint (reducing reflection) on the entire model, and sprinkle "talcum powder+coffee powder" on the ground to simulate dust; Scratches on the surface of the equipment are caused by sandpaper, and rust stains are created by spraying "rust red+brown" liquid; The pipeline support (copper wire) is coated with yellow brown paint to simulate oxidation.

Recently Posted

-

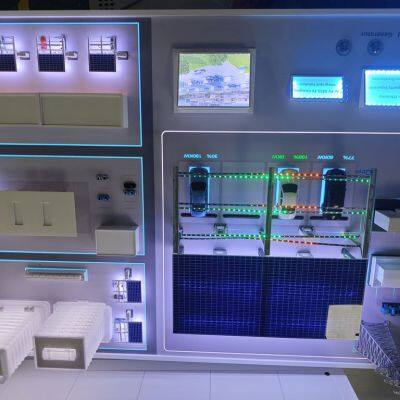

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

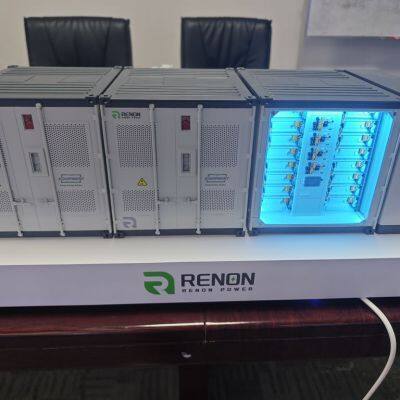

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

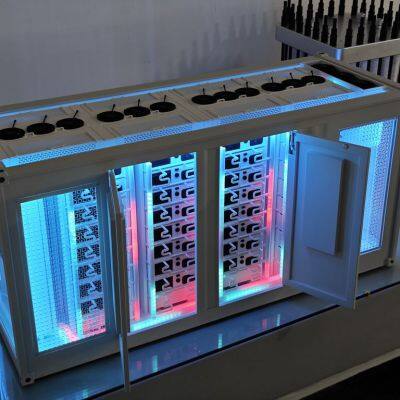

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More