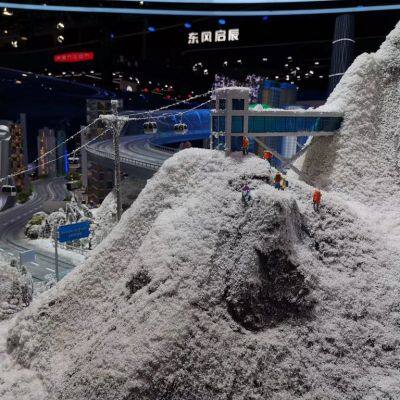

Sand table model making factory for thermal power plants

The whole process of making thermal power plant models by model manufacturers

1. Requirement docking: Clarify goals

Scene positioning: Exhibition hall/Education/Headquarters? Determine the style (branding/principle based/technical based).

Core parameters: Scale (1:100-500), Function (static/dynamic), Material (PVC/metal/acrylic), Special requirements (LOGO/data screen).

2. Design and R&D: Quickly produce cases

3D modeling: Disassemble equipment modules (boilers, turbines, etc.) using CAD, optimize structures (avoid complex surfaces, reserve installation holes).

Material selection: Main body PVC/ABS (low-cost), metal texture with imitation metal paint, transparent parts with acrylic.

Sample verification: Create functional prototypes (pipeline connections, motor drives), adjust details (chamfering, identification process).

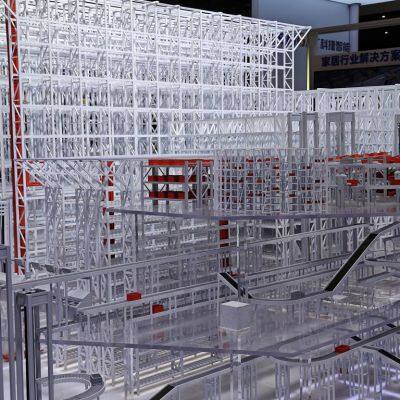

3. Large scale production: efficient manufacturing

Parts processing: laser cutting of PVC/acrylic (accuracy ± 0.1mm), CNC lathe for cylindrical parts, 3D printing of complex blades.

Surface treatment: automatic spray painting line batch color matching, UV printing LOGO/text, electroplating to enhance the metallic feel.

Module assembly: The assembly line operates in the order of "equipment → system → scene", with quality inspection at each stage (pipeline sealing, motor operation).

4. Quality inspection and delivery

Appearance quality inspection: check for scratches, color differences, and deformations; Functional test: The lighting/motor runs continuously for 24 hours without any faults.

Packaging protection: EPE foam inner support+drop resistant corrugated box, and key parts are separately shockproof.

5. After sales support

Quick response to modifications (changing molds/logos); Remote guidance maintenance (replacement of light strips/motors); Regularly push technology upgrades (such as AR interactive models).

Recently Posted

-

Manufacturer of power equipment models

September 11, 2025Case study of high-precision display model production for power equipmentThe aim of this project is to create a 1:4 scale substati Read More

Read More -

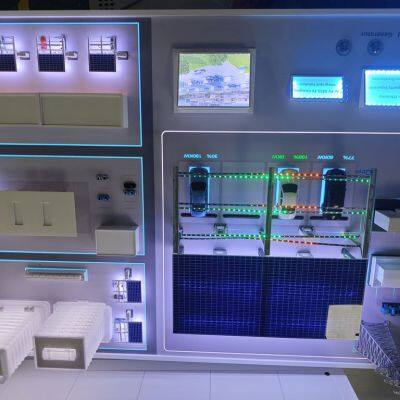

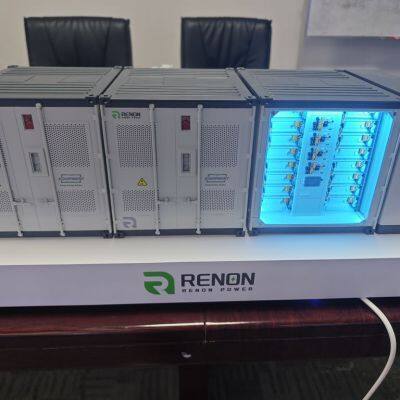

Customized manufacturer of energy storage equipment models

September 11, 2025Case study on high-precision display model production of energy storage cabinetThe aim of this project is to create a 1:5 scale en Read More

Read More -

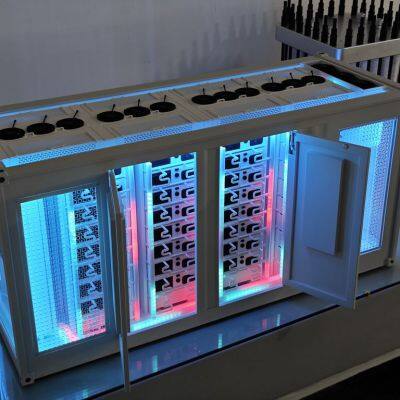

Manufacturer of energy storage cabinet model

September 11, 2025High precision display model (lighting version) production case of vertical energy storage cabinetThe aim of this project is to cr Read More

Read More -

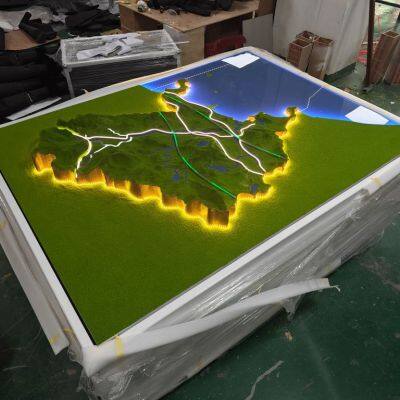

Manufacturer of energy storage device models

September 11, 2025Case Study on Model Production of Energy Storage Cabinet with Lighting DisplayThis project is a 1:5 scale energy storage cabinet s Read More

Read More